🚀 Shaping the Future - Issue 12

Join us in extending a warm welcome to Angela Thurman as she joins the Industry 4.0 Club as a founding member.

🚨 Angela Thurman joins the Industry 4.0 Club

Join us in extending a warm welcome to Angela Thurman as she joins the Industry 4.0 Club as a founding member. Angela Thurman, PMP, is a seasoned professional with over 30 years of technical project management experience in telecommunications and aerospace. She is the Founder and Principal Managing Director of Thurman Co., LLC, a prominent Project Management consulting firm based in Houston, TX. Angela's wealth of expertise will enrich our ecosystem and help advance our mission.

🧠 The Dos and Don'ts for Successful Industry 4.0 Projects

Last week’s panel explored the challenges and strategies associated with implementing Industry 4.0 solutions in manufacturing. The panel emphasized the importance of focusing on the "why" before the "how," meaning that manufacturers should first define their goals and objectives for using new technologies and data-driven insights. Tim Stuart also touched on the significance of culture change within an organization, as changing behaviors and processes is a key aspect of successful Industry 4.0 adoption and advised that when pursuing change, it's crucial to start from the top down, with leadership setting the tone for embracing these new technologies

You can listen to the conversation below or watch the show here.

📈 Key Industry Trend to Keep an Eye On

A trend to monitor is the substantial increase in manufacturing construction spending in the US, as depicted in the accompanying graphic. However, despite this surge, employment within the sector has remained stagnant over the past year, creating a challenge in sourcing the workforce needed for new factories. Notably, construction spending for US manufacturing has nearly doubled from $110 billion in May 2022 to $194 billion in May 2023, primarily fueled by projects in computer, electronic, and electrical manufacturing. This surge is occurring amid a concerning manufacturing skills gap, marked by a shortage of highly technical and manual expertise in the labor market. If left unaddressed, this gap could result in approximately 2.1 million unfilled jobs by 2030, potentially costing over $1 trillion in that year alone. This labor crisis is not unique to the US and mirrors similar challenges faced by other Western countries, underscoring the urgency required to find effective solutions.

📚What we’ve read this week

Factory of the Future [Bain]

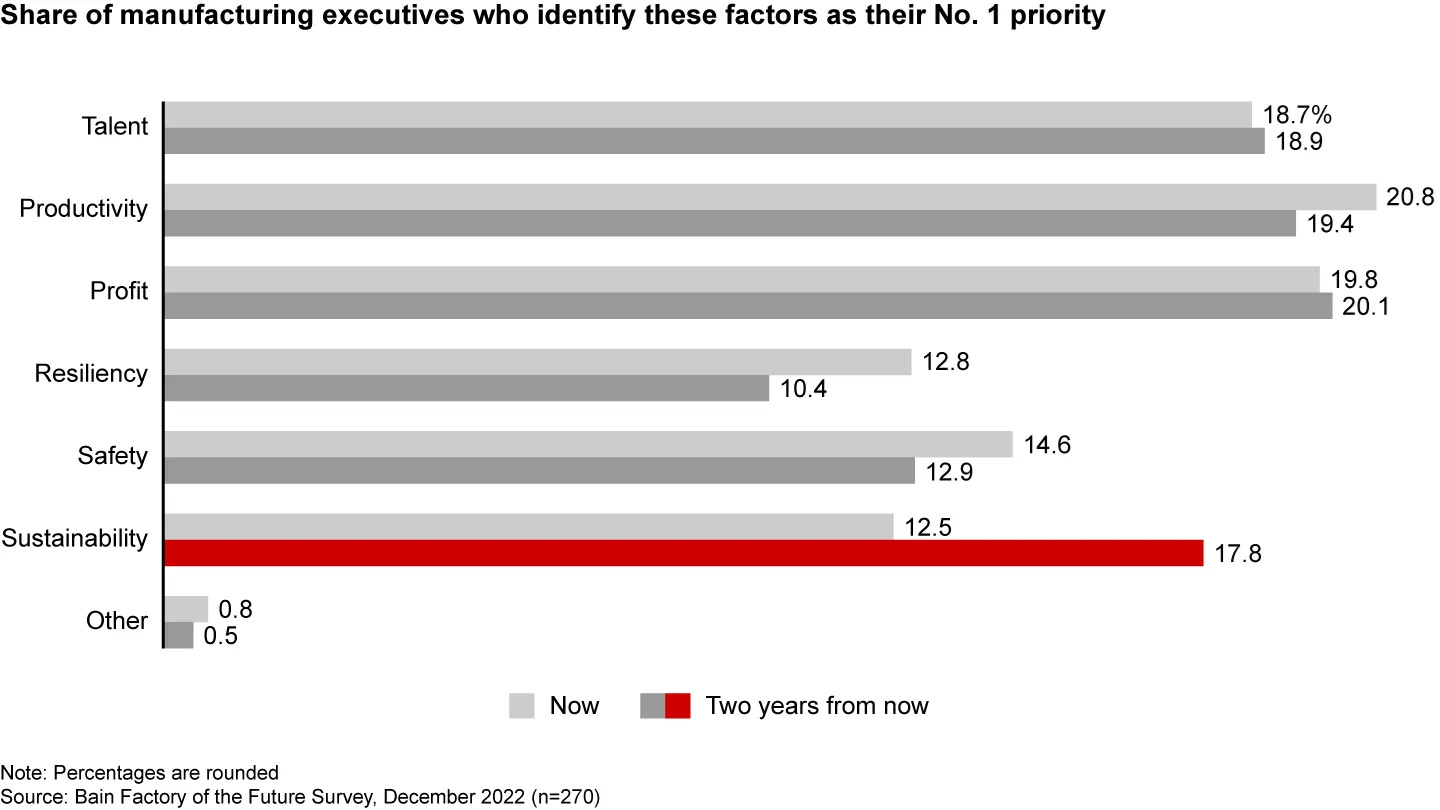

In response to challenges such as sustainability, evolving customer demands, and heightened competition, innovation becomes imperative. A novel production system strategy integrates various design principles and tools, encompassing circular design, intelligent production methods, and the adaptability of the entire production ecosystem. According to Bain, the future envisions digitally-enhanced shop floors, versatile layouts, circular value chains, and agile organizational structures. A graphical representation underscores the increasing importance of sustainability in manufacturing, set to drive significant transformations on the shop floor within the next two years.

Toyota Develops New AI for Training Robots [New Atlas]

Toyota, in collaboration with MIT and Columbia Engineering, has devised an innovative learning technique termed "Diffusion Policy," enabling robots to swiftly adapt to diverse tasks through tactile feedback provided by hand controls, while the robot's AI constructs its internal model of success and failure based on human demonstrations. Toyota aims to have hundreds of tasks mastered by year-end and a goal of exceeding 1,000 tasks by 2024, facilitated by the development of a comprehensive "Large Behavior Model" (LBM). This LBM holds the promise of empowering humanoid robots to control a wider range of human-designed tools, particularly excelling in handling deformable objects, textiles, and liquids for various applications.

Wonking Out: Making Manufacturing Good Again [NYTimes]

Amid the United Auto Workers' (UAW) negotiations for higher wages and benefits with automakers, this op-ed assesses their request in the context of U.S. manufacturing jobs' historical evolution. Pre-New Deal manufacturing jobs were often characterized by low wages and long hours. However, the 1930s and 1940s marked a notable increase in real manufacturing wages, driven primarily by unionization and the supportive New Deal political climate. This era, known as the "Great Compression," mitigated wage inequality and established a thriving middle-class society. Nevertheless, real wages in manufacturing have been on the decline since 1980, particularly in the auto manufacturing sector. This decline can be attributed to dwindling unionization rates and the weakening of union influence since their peak during the New Deal. The erosion of unionization has diminished the wage advantage that manufacturing jobs once held. Consequently, the argument posits that restoring worker bargaining power should hinge on unions, ideally extending this approach to other sectors to enhance overall working conditions.

Nvidia bets that factories will be software-designed [TechCrunch]

Nvidia's CEO, Jensen Huang, recently disclosed that the company's strategic pivot in 2018 towards AI-powered image processing, incorporating ray tracing and intelligent upscaling, has yielded significant dividends. This transformation involved a complete overhaul of their hardware, software, and algorithms. It has not only revolutionized consumer GPUs and gaming but has also proven immensely beneficial in the field of machine learning development. Huang emphasized that this is merely the initial phase, as AI-driven models are set to play a pivotal role in numerous industries, with a particular focus on manufacturing. He envisions a future where entire factories will be defined by software and robotics, and the vehicles they manufacture will also be assembled by robotic systems. In essence, it's a vision of robotically designed robots building other robots.

The Problem with Digital Twins [Atomico]

Ben Blume from Atomico recently discussed the evolution of digital twins since the 2000s, highlighting their progression from sensor-based replicas of physical systems. These digital twins have migrated to the cloud, becoming more accessible and powerful, thanks to AI and simulations. Notably, some digital twins now have the capability to directly control physical systems, promising significant advancements in smarter business operations.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!