🚀 Shaping the Future - Issue 15

This year's Southtec will place a special focus on workforce development, SMART Manufacturing, and the impactful innovators of Manufacturing USA.

🚨 See you at SOUTHTEC 2023

We look forward to see you at Southtec 2023! If you haven't registered yet, you can do so by following the provided link.

Southtec is a leading event that serves as the ultimate hub for exploring the latest advancements in manufacturing. It brings together manufacturing suppliers, distributors, and equipment builders from across North America and around the globe, with hundreds of exhibiting companies offering cutting-edge technologies and services. Attendees have the opportunity to connect with experts who can showcase solutions to help grow their businesses.

This year's Southtec will place a special focus on workforce development, SMART Manufacturing, and the impactful innovators of Manufacturing USA. Each event in the Manufacturing Technology Series gathers decision-makers, technology suppliers, and thought leaders from various manufacturing disciplines for an exceptional three-day experience. We look forward to your participation at this event.

🧠 OT Cybersecurity Stew

Securing OT systems, especially in the context of legacy equipment, involves various best practices. Since every OT environment is unique, and the best practices may vary. It's crucial to conduct a risk assessment, understand the specific risks facing your legacy systems, and tailor your cybersecurity strategy to address those risks effectively. Last week’s OT Cybersecurity Stew was full of best practices on how to stablish a cybersecurity program at an organizational level that involves both IT and OT stakeholders and fosters collaboration, aligning cybersecurity objectives with operational goals.

That episode definitely deserve a repeat, you can listen to the conversation below or watch the show here.

📈 Key Industry Trend to Keep an Eye On

Our trend of the week is anomaly detection. Anomaly detection is a critical aspect of modern manufacturing, where data-driven insights are revolutionizing operations. It involves the identification of irregular data points or patterns that deviate from the expected norm. In manufacturing, anomalies often signal defects or issues in the production process, which, if left unaddressed, can lead to significant losses for manufacturers. Implementing robust anomaly detection systems enables proactive problem-solving, reduces downtime, and enhances product quality, making it a trend of paramount importance for efficiency and profitability in the manufacturing sector.

📚What we’ve read this week

Why Predictive Maintenance in Manufacturing is at a Crossroads [Falkonry]

Predictive maintenance in manufacturing has gained attention but faces limitations due to challenges such as insufficient predictive data and ever-changing operational dynamics. Anomaly detection emerges as a more effective strategy, focusing on minimizing excursion risks and enhancing efficiency. It offers broader coverage by learning from normal behavior, reducing the time spent on troubleshooting and recovery. Anomaly detection operates on the premise that computers understand instrumented behavior, making it a more practical and adaptable approach compared to the traditional predictive maintenance method. The future of predictive maintenance in manufacturing lies in individualized fault detection and resolution, aligning with the goals of efficient maintenance and reliable operations in an evolving manufacturing landscape.

Quantifying the impact of anomaly detection [Falkonry]

The article discusses the significance of quantifying the impact of anomaly detection, especially in the context of AI for achieving Smart Operations. It introduces the concept of the "Beneficial detection rate" (BDR), which measures AI's success in identifying events that have a high potential to improve operations. A high initial BDR, such as 15%, is considered financially viable and can lead to substantial annual productivity gains, especially in large facilities. The text highlights how this metric, in combination with trust in AI's explanations, encourages adoption by demonstrating its potential for cost savings and operational enhancements. It emphasizes that beneficial detection encompasses both addressed issues and detections that contribute to future problem avoidance, making it a valuable tool in decision-making for AI adoption in operations.

Coping with ongoing supply chain volatility [Flexware Innovation]

The recent years have brought about a transformation in supply chain management, highlighting the need for increased resilience alongside efficiency. The COVID-19 pandemic revealed the vulnerability of highly efficient yet inflexible "just-in-time" inventory practices, prompting companies to pivot towards agility. Ongoing challenges, including geopolitical instability, cyberattacks, trade wars, extreme weather events, and the persistent threat of pandemics, continue to disrupt global supply chains. To address these issues, manufacturers are adopting strategies such as flexible manufacturing, diversifying supplier bases, embracing digital transformation, increasing safety stock, and fostering collaborative partnerships to enhance adaptability and resilience. In this evolving landscape, the focus is on building a more robust and flexible global supply chain for the future.

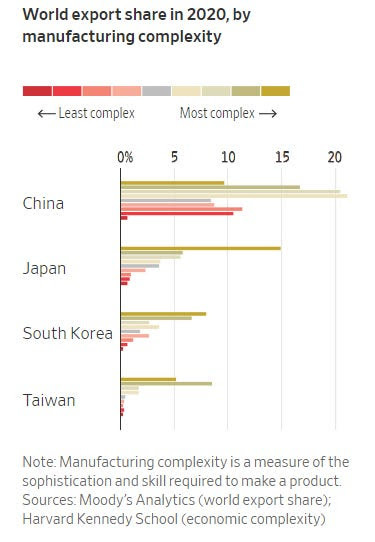

China’s Factory Floor Is Moving—But Not to India or Mexico [WSJ]

Despite Western attempts to reduce reliance on Chinese manufacturing, China's global manufacturing dominance remains robust, with its inland provinces emerging as formidable contenders against countries like Mexico, India, and Vietnam. This shift is fueled by the pursuit of cost advantages, affordable labor, ample factory space, and stricter environmental regulations in China's coastal cities. Consequently, exports from China's interior regions have surged, surpassing the export growth of competing nations. China's ongoing emphasis on developing its inland areas for integrated national economic growth endures, with the interior specializing in labor-intensive, low-value-added manufacturing, while the coastal regions focus on advanced industries.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!