🚀 Shaping the Future - Issue 18

ATX West returns to Anaheim, California on February 6-8, 2024, uniting the greatest minds in automation to advance manufacturing excellence!

🚨 Registrations for ATX West are Now Open!

ATX West returns to Anaheim, California on February 6-8, 2024, uniting the greatest minds in automation to advance manufacturing excellence! Dedicated to inspiring the evolution of automation solutions, ATX West is where you can find expert-led education, partnerships with visionary engineers and suppliers, and leading product innovations across the advanced manufacturing industry.

🧠 Is Your Company's Data Improving Your Business Results?

Last week's Fireside Chat highlighted AI's various promises and potential, especially in traditional applications like preventative maintenance, quality control, and classification models. However, the key is to focus on real business problems and use cases rather than getting caught up in the hype of new technologies. The successful application of AI requires a thoughtful and strategic approach, starting with understanding the specific challenges and goals of the business as the transition to a more data-driven and analytics-savvy organization should be gradual, with a blended team approach that involves both external expertise and internal talent to build sustainable capabilities over time.

👩🔧 Lightbulb Moments in Smart Manufacturing Adoption

Last week’s Women in Manufacturing featured a discussion on the intersection of sustainability, manufacturing, and technology in the context of Industry 4.0. The conversation emphasized the role of software and data in driving sustainable practices in manufacturing, citing examples of benchmarking and small changes that can lead to significant impacts on efficiency and resource consumption while also touching on the role of open source and open standards in smart manufacturing, fostering collaboration and adaptability.

You can listen to the conversation below or watch the show here.

📈 Key Industry Trend to Keep an Eye On

The US industrial manufacturing sector is grappling with a worsening labor shortage driven by retirements, workforce migration for better pay, and difficulties attracting younger talent skilled in managing Industry 4.0 technologies. McKinsey predicts a 30% decline in demand for traditional skills and a 50% increase in demand for technical skills over the next decade. The shortage could lead to 2.1 million unfilled jobs by 2030, costing the industry $1 trillion. Manufacturers are responding by raising wages, implementing employee retention strategies, and reskilling workers for digital-focused roles. Modernizing facilities, introducing robotics, and promoting continuous learning aim to improve the work environment. To overcome workforce shortages, manufacturers are also focusing on reskilling programs, diversifying the workforce by attracting more women and underrepresented ethnic groups, and participating in national initiatives such as America’s Cutting Edge and Creators Wanted.

📚What we’ve read this week

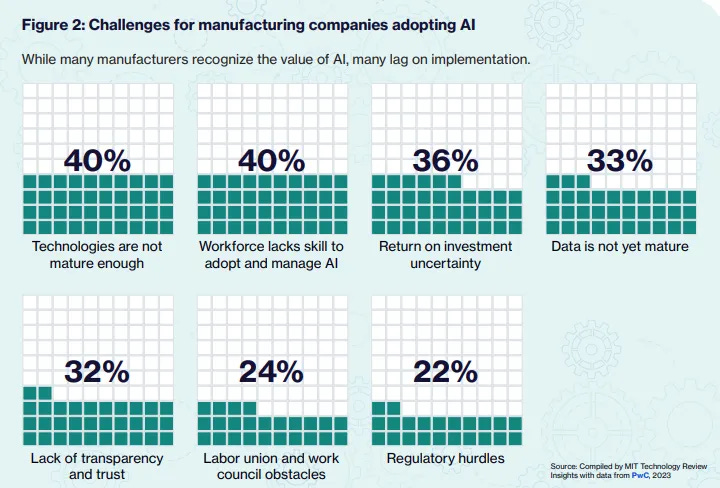

AI Momentum in Core Manufacturing Services [MIT Technology Review]

Manufacturers are leveraging AI to streamline operations, reduce downtime, incorporate robotics for safety and speed, detect anomalies using computer vision, and process vast amounts of data to identify patterns and predict customer needs. The study from Dataiku indicates that while the manufacturing sector has been innovative in response to supply chain disruptions and labor shortages, it still lags behind other industries in terms of AI adoption, with a significant portion of companies in the exploration or experimentation phase.

The Gen Z Industrial Work Report [Soter Analytics]

Here are the Key Highlights:

Gen Zers are uninterested in industrial jobs: Only 14% say they’d consider industrial work as a career; 26% say they’d only consider it for a short-term career.

Perceptions of poor pay and promotion opportunities: Some 46% of Gen Zers surveyed listed pay as a top reason for considering a job, and 29% said that if industrial jobs paid above average for entry-level workers they’d consider them. But one in five of those surveyed believe industrial work pays poorly. Meanwhile, 32% of Gen Zers said they’d consider industrial work if there were a clear path to a corporate position.

Perceptions of poor flexibility and safety: Flexible hours are important, according to 40% of survey respondents, and 26% of Gen Zers said they believed industrial work did not offer flexible hours. Meanwhile, a quarter of Gen Zers believe industrial work is not safe.

The Trillion-Dollar Quest to Make Green Steel [Canary Media]

The current process of heating fossil fuels to produce steel contributes significantly to global CO2 emissions, prompting the need for "green steel" solutions with lower carbon footprints. One approach involves using hydrogen to process iron ore, exemplified by projects like Hybrit in Sweden. Green steel production leverages renewable energy for electric arc furnaces, reducing emissions from melting iron and steel scrap. To scale up green steel, government policies incentivizing cleaner production and fostering collaboration between suppliers and industries are crucial. Additionally, companies must focus on retraining workers for greener technologies, and the automotive industry, a major steel consumer, should establish clear goals to drive the adoption of cleaner production methods.

How to harness operational data to meet sustainability targets [Smart Industry]

Manufacturing companies face a significant challenge in meeting sustainability demands, grappling with issues such as water scarcity, wastewater treatment, energy conservation, and emissions reduction. A recent study reveals a notable correlation between companies that communicate their efforts toward environmental, social, and governance (ESG) goals and cumulative growth, emphasizing the importance of sustainability claims. Operational data emerges as a key solution, enabling manufacturers to enhance their environmental impact, public perception, and bottom-line goals. Leveraging vast amounts of time-series data from sensors and contextual information, such as maintenance records, operational data empowers engineers to optimize processes, predict maintenance needs, and achieve sustainability objectives. Through advanced industrial analytics and machine learning, manufacturers can address unique challenges, improve operational performance, and make significant cost savings, ultimately contributing to a more sustainable future.

Amazon’s Tye Brady on the Future of Robotics [Techcrunch]

During Amazon's "Delivering the Future" event, the company unveiled significant strides in its robotics endeavors, boasting a fleet exceeding 750,000 mobile robots and other robotic systems in its operations. Notable highlights include the introduction of the Sequoia Inventory System, capable of accelerating inventory identification and storage at fulfillment centers by an impressive 75%. Amazon also emphasized the integration of generative AI into robotics applications, spanning tasks from generating synthetic packages for system testing to optimizing grasp affordance. Pilot programs with Agility's Digit robotic systems aim to assess the viability of bipedal/humanoid robots, while the exploration of mobile manipulation involves mounting robotic arms on Autonomous Mobile Robots (AMRs). These initiatives underscore Amazon's commitment to pushing the boundaries of innovation and efficiency in its ever-expanding operational landscape.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!