🚀 Shaping the Future - Issue 22

We unveil the fourth reveal of the Advanced Engineering sessions scheduled for ATX West, set to unfold in Anaheim, California, from February 6-8, 2024.

🚨 The Industry 4.0 Club will be at ATX West

ATX West returns to Anaheim, California, on February 6-8, 2024, uniting the greatest minds in automation to advance manufacturing excellence. The Industry 4.0 Club will be hosting the Advanced Engineering panels.

Stay tuned over the next few weeks as we unveil the distinguished guests and topics to be featured at the conference. Don't miss out – registration is now open. Secure your spot to be part of this conference.

🧠 Data: Gather, Analyze, Interpret, and Act

During last week’s Fireside Chat, Amanda Walden, the President of Chemical Methods, discussed her journey from being a chemist to a leadership role. The discussion touched on the potential for substantial savings for clients, when data is embedded within a continuous improvement process that turns data into insights.

You can listen to the conversation below or watch the show here.

🤖 Develop personal and customer GPTs for Manufacturing

Last week’s Manufacture Future episode focused on the latest ChatGPT updates. OpenAI has introduced a feature where users of the latest version of OpenAI's GPT, known as OpenJ GPT, can create custom GPTs with specific learning to generate responses based on defined criteria. This allows users to develop tools that respond in specific ways. The conversation touched on potential applications in manufacturing, such as employee training, but emphasizes the technology's evolving nature and the need for caution, particularly in sensitive environments.

You can listen to the conversation below or watch the show here.

📣 Preview of Upcoming Advanced Engineering Sessions at ATX West 2024

We unveil the fourth reveal of the Advanced Engineering sessions scheduled for ATX West, set to unfold in Anaheim, California, from February 6-8, 2024.

📌 Title: Manufacturing in the USA: Productivity Plateaus, Paradoxes, and Proven Solutions

📝 Abstract: Industrial Manufacturing has gone through four major revolutions since the first mechanical loom in 1784, from the introduction of mechanical systems powered by water and steam to the latest Industry 4.0 cyber-physical systems. LNS’s research shows that manufacturing companies are investing heavily in industrial transformation and that the companies that invest correctly are achieving significant results. The paradox is that, even with major innovation and investments, labor productivity has stagnated since the Great Recession. In this session, we will explore the reasons for the stagnation and eight proven solutions for transformation.

👤 Presenter: Niels Andersen, Principal Research Analyst - Factory of the Future

✍️ Bio: Niels Andersen conducts research on a broad range of Industrial Transformation topics, utilizing his 30+ years of experience in industrial technology and software, and has held executive positions at industry-leading organizations. Main coverage areas: Factory of the Future, IX Readiness, Industrial Analytics, Software Architecture.

📚What we’ve read this week

Energizing American Battery Storage Manufacturing [SEIA]

The Solar Energy Industries Association (SEIA) has released a report highlighting barriers to building a robust energy storage manufacturing sector in the U.S., despite the Inflation Reduction Act (IRA) strengthening competitiveness. The report identifies challenges such as cost competitiveness, access to raw materials, technical expertise, and the need for a diverse workforce. While the IRA supports domestic production, the report suggests that without strategic action, the U.S. may face a shortfall in energy storage supply by 2025 due to growing global demand, driven by the IRA's incentives for solar investment. The main challenges include the cost and availability of raw materials, with a focus on graphite and processed materials. The report emphasizes the importance of federal incentives and outlines potential reductions in energy storage costs. It also highlights the need for longer development times, workforce training, and effective state regulations to support domestic energy storage production as a strategic imperative for U.S. energy security.

Manufacturers Go All-In on AI [MLC Survey]

Results from the Manufacturing Leadership Council’s 2023 Transformative Technologies survey point towards increased interest in AI & machine learning and robotics & digital twins being the technologies that companies believe will have the greatest impact on manufacturing operations.

Global Automakers Turn To China for EV Lessons [WSJ]

Major international car manufacturers such as Volkswagen, Nissan, and Toyota are actively incorporating lessons from China's electric vehicle (EV) industry to align with the increasing trend toward electric vehicles in the Chinese market. Western automakers are keen on optimizing their production processes, reducing development timelines, and bolstering digital capabilities to effectively compete with nimble Chinese counterparts. The ramifications of this shift extend beyond the Chinese market, as manufacturing methodologies and digital technologies from China may have a broader influence on global automotive manufacturers. Volkswagen, for example, is prioritizing agility, localized decision-making, and collaboration with Chinese suppliers to expedite its vehicle development procedures. Likewise, other global automakers like Nissan and Toyota are adopting strategies acquired from their Chinese joint ventures to remain competitive in the dynamic landscape of the automotive industry.

Boosting Rocket Reliability at the Material Level [MIT News]

SpaceX's Starship and Blue Origin's next-generation reusable rockets have the potential to significantly cut launch costs and increase accessibility to space. However, recent setbacks, such as the explosion of SpaceX's Starship prototype, highlight notable reliability issues. To address these challenges, MIT's Cordero Lab is actively engaged in research leveraging additive manufacturing (AM), materials engineering, and structural design. The primary objective is to bolster the reliability of reusable rockets at the materials level, with a specific focus on critical components like turbopumps, thrust chambers, and nozzles. The lab is exploring the application of AM to create innovative materials that enhance reliability and allow for more intricate designs. A key hurdle involves addressing oxidizer compatibility in propulsion devices, which often results in high-temperature, high-pressure oxygen environments leading to metal fires and rapid failure. Consequently, the lab is undertaking projects involving the development of oxygen-compatible ceramic coatings featuring metallic ductile phases to withstand rapid thermal transients. Additionally, the lab is working on crafting friction-resistant alloys for components susceptible to frictional ignition.

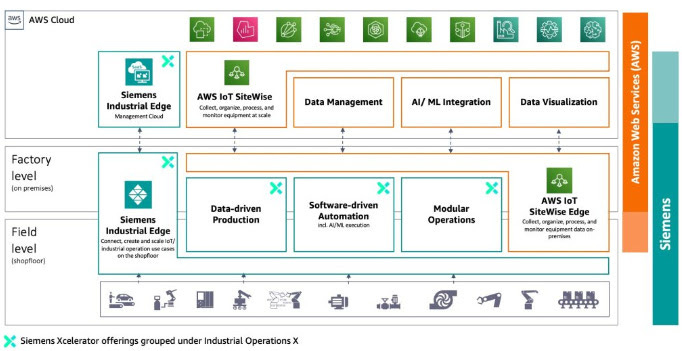

AWS and Siemens OT-IT Integration [AWS Industry Blog]

Amazon Web Services (AWS) has announced that AWS IoT SiteWise Edge, an on-premises software for collecting and processing equipment data, can now be deployed directly from the Siemens Industrial Edge Marketplace. This collaboration aims to bridge the gap between Operational Technology (OT) and Information Technology (IT) in the industrial sector, facilitating the integration of machine data into the AWS cloud. The goal is to simplify, accelerate, and reduce costs associated with sending industrial equipment data to the cloud. The integration is crucial for achieving digital transformation in the manufacturing sector, breaking down data silos, and enabling benefits such as enhanced efficiency, data-driven decision-making, improved security and compliance, cost savings, and scalability. The deployment leverages Siemens Industrial Edge infrastructure, facilitating a more efficient and cost-effective data pipeline between machines and the cloud.

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!