🚀 Shaping the Future - Issue 23

Our Women in Manufacturing hosts are gearing up for an insightful 'Looking Back at '23 and Ahead at '24 - Year End Panel' happening this upcoming Tuesday.

🚨 The Industry 4.0 Club will be at ATX West

ATX West returns to Anaheim, California, on February 6-8, 2024, uniting the greatest minds in automation to advance manufacturing excellence. The Industry 4.0 Club will be hosting the Advanced Engineering panels.

Stay tuned over the next few weeks as we unveil the distinguished guests and topics to be featured at the conference. Don't miss out – registration is now open. Secure your spot to be part of this conference.

📝 The Intelligence of Things

Industry 4.0 relies on fundamental technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI), particularly Machine Learning (ML). The convergence of IoT and AI into the Artificial Intelligence of Things (AIoT) aims to connect and collect real-world data while rapidly analyzing and extracting insights using AI. However, challenges arise due to the computational demands of many ML models, requiring high-performance computing power. The key issue is compressing ML models to fit resource-constrained Edge and IoT devices, addressing latency and bandwidth concerns. Deploying ML at the edge enables real-time automation processes, eliminating the need for data transfer to centralized servers and enhancing data privacy. The Intelligence of Things presents benefits such as reduced latency, bandwidth usage, and improved data privacy, making it a crucial aspect of Industry 4.0 for efficiency and automation. Further exploration into the practicalities of the Intelligence of Things in Industry 4.0 is anticipated in subsequent articles.

📣 Preview of Upcoming Advanced Engineering Sessions at ATX West 2024

We unveil the fifth reveal of the Advanced Engineering sessions scheduled for ATX West, set to unfold in Anaheim, California, from February 6-8, 2024.

📌 Title: The Need for Digital Solutions to Meet FDA Part 11 Validation

📝 Abstract: Few industries require as much focus on quality management, process efficiency, and regulatory validation as Medical Devices. In a space where shortcomings can mean the difference between life and death, stakes are high and technological innovation is critical in meeting the demands and overcoming the limitations medical device manufacturers face. Many of today’s leading medical device manufacturers are finding innovation through digital manufacturing solutions. The Medical Device industry builds many critically complex, intricate and complicated products while being challenged by pressures of cheaper, faster, safer and better innovation. Digital manufacturing platforms provide an innovative approach to simplifying how complex manufacturing, quality, and post sale service processes are managed and improved. On top of this, digital solutions help manufacturers to maintain quality and regulatory compliance, particularly FDA 21 CFR Part 11 validation, which has become an increasingly important obstacle to overcome and one that is top of mind for all medical device manufacturers. In this discussion, Sung Kim, Chief Product and Technology Officer at iBase-t, will provide an overview of the advantages medical device manufacturers can unlock through digital solutions. Sung Kim will discuss the heightened need for medical device manufacturers to use digital solutions to meet the rigorous standards of FDA Part 11 validation.

👤 Presenter: Sung Kim, Chief Product and Technology Officer at iBase-t

✍️ Bio: Sung is an experienced technology architect and a published computer scientist with more than 20 years of experience. During his tenure at iBASEt, he played a key role in enhancing Solumina’s technology and exploring architecture experiments for future product directions. As the CTO, Sung leads iBASEt’s long-term technology vision and is responsible for the overall product architecture and infrastructure deployment profiles, focusing on open standards and integration technologies. He also facilitates the technical community within iBASEt. Prior to joining iBASEt, Sung worked in the telecommunications industry and in academics teaching undergraduate and graduate students. His research works have been published in various International Journals and Conferences including ACM and IEEE transactions and conferences. Sung holds Master’s and PhD degrees in Computer Science from the University of Texas.

📚What we’ve read this week

Anticipated and emerging manufacturing trends in 2024 and beyond [The Manufacturer]

The manufacturing industry is poised for significant transformations in the coming years. Firstly, digital transformation and the convergence of IT/OT will accelerate, with a focus on combinatorial innovation driven by technologies like AI, machine vision, and robotics. Secondly, automation will address the manufacturing sector's primary challenge of worker attrition, with a shift toward advanced software solutions and gamification to enhance worker enablement. Thirdly, AI/ML technologies will advance to the next level, emphasizing edge intelligence to operate more efficiently without unnecessary data transfer. Additionally, a new bio-evolution phase requires transparency in supply and cold chains, particularly in food and pharma manufacturing. Lastly, manufacturers will increasingly turn to RFID and machine vision solutions for locationing, enhancing efficiency and traceability, especially in automotive battery manufacturing. These trends underscore a comprehensive shift towards technology-driven, efficient, and transparent manufacturing processes.

The Economic Downsides of Right to Repair [NAM]

A study commissioned by the National Association of Manufacturers (NAM) suggests that "right-to-repair" policies, which are currently in place in over 30 states, could have negative economic impacts. The study, titled "The Economic Downsides of ‘Right-to-Repair,’” states that such policies might disrupt supply chains, increase the risk of intellectual property theft for manufacturers, raise costs for both consumers and manufacturers and potentially lead to an increase in greenhouse gas emissions. The study argues that these policies could result in unintended and harmful consequences, making product repair more challenging and increasing compliance costs for manufacturers.

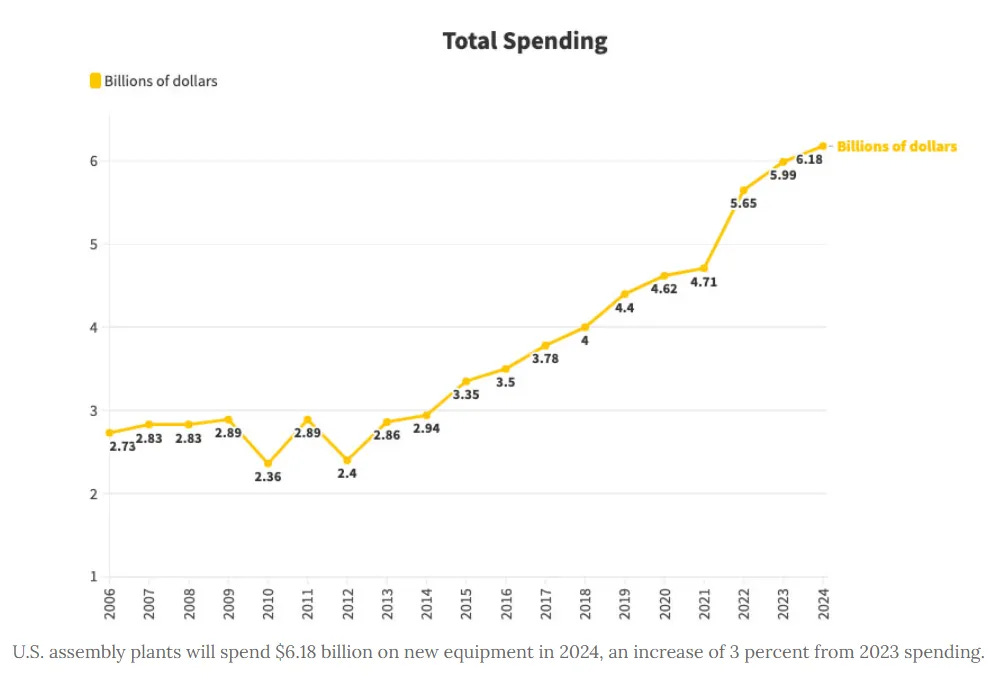

2023 Manufacturing Capital Spending Survey [Assembly Magazine]

Here are some highlights from Assembly Magazine’s 28th Annual Capital Equipment Spending Survey:

U.S. assembly plants will spend $6.18 billion on new equipment in 2024, an increase of 3 percent from the $5.98 billion projected to be spent in 2023.

The Automotive industry will account for 63 percent of all spending next year and automotive assemblers will spend $7,786,111 on capital equipment next year, 4x the national average.

After accounting for more than 30 percent of total equipment spending in each of the past two years, machinery manufacturers (NAIC 333) will represent just 2 percent of spending in 2024.

The Midwest has traditionally been the epicenter of U.S. manufacturing, and next year will be no exception. The region will account for 52 percent of spending in 2024, more than any other part of the country and the most for the region since 2018.

“The world record of 500,000 units was exceeded for the second year in succession,” says Marina Bill, president of IFR and group vice president for robotics and discrete automation at ABB Inc. “In 2023, the industrial robot market is expected to grow by 7 percent to more than 590,000 units worldwide.”

We expect sales of six-axis robots, SCARAs, grippers, and other robotic technology to increase 11 percent, from $720 million in 2023 to $799.4 million in 2024.

Looking to Maintenance to Boost Semiconductor Efficiency [McKinsey]

The global semiconductor industry is poised for a 6 to 8 percent annual growth until 2030, targeting a $1 trillion annual revenue, with 40% stemming from industries reliant on mature nodes like automotive, industrial, and wired communication. However, aging facilities (fabs) managing mature node manufacturing are grappling with increased demand and downtime issues. Enhancing equipment reliability can boost tool availability by over 15%, contributing to a 70 to 80 percent overall equipment effectiveness (OEE) increase. To address these challenges, fab leaders must transition from reactive to preventive approaches, emphasizing equipment recovery, consistent planned maintenance, and efficient parts management. Best-in-class planned maintenance programs can elevate fab availability by 5 to 7 percentage points, necessitating top management commitment, accountability, and continuous improvement. A recommended control tower approach with real-time data analysis is crucial for optimizing parts management and addressing related challenges.

The Manufacturing Shift Is Affecting Shipping [QZ]

Despite challenges such as collapsing container rates and overcapacity affecting the global shipping industry, intra-Asia shipping stands out as a bright spot, driven by manufacturers diversifying their supply chains. Vietnam has emerged as a critical node in global trade flows, experiencing a surge in foreign investment and increased manufacturing activity. Direct shipping routes between Vietnam and the US have nearly doubled, marking a significant rise in Vietnam's ranking for countries with direct shipping services to the US. The maritime transport industry in Vietnam is thriving, with an 83% increase in scheduled deployed capacity between the US and Vietnam from 2019 to 2023. While China remains pivotal in global trade, the trend of diversification is evident as Vietnam becomes an extra call in shipping routes, underscoring Asia's role as the world's manufacturer. To fully leverage increased intra-Asia shipping, Vietnam requires essential infrastructure investment, potentially from China, which has shown interest in port investments across Asia as a strategic form of "port diplomacy" to enhance global leverage.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!