🥂 Cheers to an Incredible 2023 🥂

Thank you to each member for a year of collaboration, insights, and growth. Your contributions made it truly remarkable. There's even more to be excited about in 2024, as it will be a year filled with innovation, shared learnings, and impactful conversations. Together, we'll continue shaping the future of Industry 4.0.

Wishing you a joyous and prosperous New Year 2024! May it be filled with new opportunities, exciting adventures, and moments of growth. Here's to a year of success, good health, and happiness for you and your loved ones.

Happy New Year!🥂

🚨 The Industry 4.0 Club will be at ATX West

ATX West returns to Anaheim, California, on February 6-8, 2024, uniting the greatest minds in automation to advance manufacturing excellence. The Industry 4.0 Club will be hosting the Advanced Engineering panels.

Stay tuned over the next few weeks as we keep unveiling the distinguished guests and topics to be featured at the conference. Don't miss out – registration is now open. Secure your spot to be part of this conference.

👩🏭 Women in Manufacturing Year End Panel

The Women in Manufacturing team celebrated a year of impactful conversations, collaboration, and growth. With a focus on Industry 4.0, the show featured inspiring women who shared insights on robotics, data collection, automation, and more. Notable moments included live panels at manufacturing stages and collaborations with organizations like the Society of Women in Engineering.

The club remains committed to supporting women in the industry and anticipates further growth and collaboration. You can listen to the conversation below or watch the show here.

📣 Preview of Upcoming Advanced Engineering Sessions at ATX West 2024

We unveil the sixth reveal of the Advanced Engineering sessions scheduled for ATX West, set to unfold in Anaheim, California, from February 6-8, 2024.

📌 Title: AI and Cybersecurity in Industry 4.0: Promises, Pitfalls, and Pathways Forward

📝 Abstract: In the dynamic world of Industry 4.0, the melding of physical and digital systems offers unprecedented opportunities for growth and innovation. Central to this fusion is the application of Artificial Intelligence (AI) - a force reshaping sectors from Biomedical to Energy. Yet, AI weaves its transformative web and spins a complex tapestry of cybersecurity challenges. This talk navigates these intricate threads, delving deep into the strengths and vulnerabilities that AI introduces across critical sectors.

👤 Presenter: Thomas Ryan, Founder, Asymmetric Response

✍️ Bio: With over two decades of experience in both cyber and physical security, Thomas Ryan stands as a highly accomplished and sought-after expert in the field. His specialties include cybersecurity mergers and acquisitions, special projects, red team operations, application supply chain security, and personal protection. Thomas's prowess stretches across offensive and defensive security operations, significantly impacting both public and private organizations.As the Founder of Asymmetric Response, a boutique security firm, Thomas has carved a unique niche in cybersecurity. Beyond his leadership role at Asymmetric Response, he also dons the hat of a Board Advisor for numerous influential companies. This vast array of roles equips him with an unparalleled depth of knowledge, which, when shared, can drastically bolster an organization's security posture and risk management programs.In 2010, Thomas was thrust into the global limelight with his groundbreaking research on the dangers and threats posed by social media – widely recognized as the "Robin Sage Experiment". The resonance of this research is undiminished even today. Its concepts are now being imparted in 28 esteemed universities worldwide and have found mentions in hundreds of pivotal security research papers. Furthermore, in acknowledgment of his relentless pursuit of cybersecurity excellence, Thomas has been credited with several CVEs for the exploits he discovered. His exceptional work has earned him accolades and has found its way to being referenced thrice in the prestigious MITRE ATT&CK Framework.Thomas's contributions to the world of cybersecurity are profound and enduring, making him an invaluable asset to any organization or conference seeking to elevate its understanding of digital threats and defenses in today's dynamic environment.

📚What we’ve read this week

‘Making It in America’ calls for a manufacturing revival [Washington Post]

In her book "Making It in America," journalist Rachel Slade argues that the United States should reorient its manufacturing focus domestically, challenging the current trend of importing a vast array of goods. Slade contends that since the implementation of NAFTA in 1994, over 60,000 U.S. manufacturers have closed, resulting in job losses and unfavorable working conditions. The book illustrates the challenges faced by American businesses striving for ethical manufacturing, using the example of American Roots, an apparel company in Maine. Slade emphasizes the need for a renaissance in U.S. manufacturing, proposing a more reasonable system of tariffs, subsidies, and regulations to incentivize domestic production and fair treatment of workers. The narrative highlights the difficulties faced by businesses attempting to prioritize ethical practices in the current market, with potential political and ecological benefits if the U.S. were to produce more of its imported goods domestically.

State of the Manufacturing + Distribution Vol 2 [Sikich]

A report from technology firm Sikich indicates a drop in optimism among manufacturing and distribution executives, with the average score falling from 6.88 to 6.76 out of 10 between March and August. Interest rates were cited as the biggest factor contributing to this decline, followed by poor economic conditions, labor costs, and increased labor shortages. Despite challenges, 92% of manufacturers successfully implemented at least one technology project in the last three years. Executives believe marketing and customer service would benefit most from artificial intelligence, with 19% already implementing AI in their daily operations. Finally, on cybersecurity, executives rated their efforts a seven out of 10 on average, but 34% experienced an information security breach in the last five years.

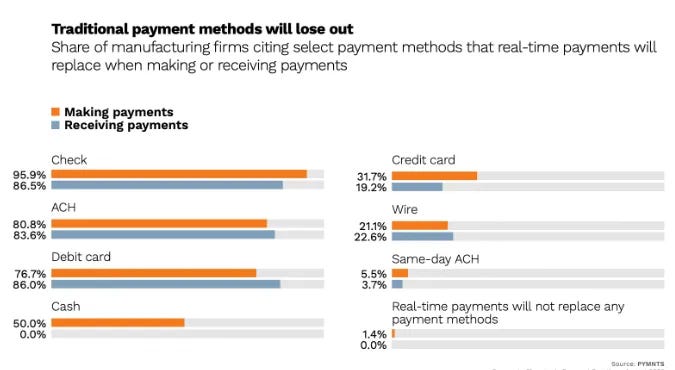

Manufacturing Companies Embrace Real-Time Payments [PYMNTS]

The report focuses on the growing interest and adoption of real-time payments within the manufacturing sector. Based on a survey of 125 decision-makers from manufacturing firms in the United States, the study reveals that 96% of manufacturers expect real-time payments to replace traditional checks for making payments, and 87% anticipate the same for receiving payments. Additionally, the study suggests a decline in the importance of traditional payment methods such as automated clearing house (ACH) payments and debit cards. About 81% of firms expect real-time payments to replace standard ACH payments for making payments, and 84% predict the same for receiving payments. Similarly, 77% of respondents foresee real-time options replacing debit cards for making payments, while 86% anticipate the same for receiving payments. Finally, the study highlights that half of the manufacturing companies surveyed expect real-time payments to displace cash, and 32% foresee the method replacing credit cards for making payments. This suggests that, while real-time payments will revolutionize the industry, traditional payment methods will still play a role in financial transactions.

Toyota Outlines Future Production Processes [Assembly]

Toyota is overhauling its production strategy to embrace electric vehicles (EVs) with advanced technologies like giga-cast modules, self-propelled assembly lines, and digital twin technology. The next-gen EVs will feature a modular structure dividing car bodies into front, center, and rear sections for improved efficiency and flexibility. Giga-casting technology reduces cost and weight in integrated cast parts. A self-propelled assembly line, utilizing autonomous driving technologies, eliminates conveyors, enabling flexible factory layouts. Digital twin technology optimizes two-way production processes to enhance productivity. Toyota is also revolutionizing employee workflows by incorporating 3D drawings and involving later-stage production workers in the design process, reducing lead times and reworking. This strategic approach underscores Toyota's commitment to a more human-centered manufacturing model while integrating Industry 4.0 technologies for the future of carmaking.

The driving force behind Canada's manufacturing future [Northern Ontario Business]

Canada's manufacturing sector is in transformation, with youth playing a pivotal role in driving change. Manufacturers are encouraged to align with future industry needs by embracing new technologies and mentoring youth in manufacturing careers. Government-funded programs, like EMC's Work Integrated Learning initiatives, develop essential skills and create pathways for youth to enter the sector. Today's digitally savvy youth can implement cutting-edge technologies, addressing skills gaps and streamlining operations. Fostering a culture of continuous learning and mentorship is crucial for shaping the industry's future. Empowering young people through education, technology adoption, sustainability, and leadership development ensures a prosperous and innovative future for Canada's manufacturing industry.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!