🚀 Shaping the Future - Issue 39

The 9th Annual State of Smart Manufacturing Report from Rockwell Automation shares insights from their largest survey group yet, with more than 1,500 manufacturers in 17 countries.

📣 Be a guest in our “Lean Industry 4.0: Operational Excellence meets Technology” Series

We're inviting knowledgeable members to join hosts Mike Ungar and Tim Stuart in our latest series titled "Lean Industry 4.0: Operational Excellence meets Technology" and share the experience and expertise on various topics including:

- Scratching the Surface: Using Data to Drive Business Results

- Enhance Lean with Digital Tools

- The IT/OT Embrace: Bridging the Divide

- Changing Standard Work with a Digital Twist: Adapting Manufacturing Practices

- Prepare Your Workforce for Success in the Digital Era

- Empowering your Workforce with Technology

To participate, just fill out this form and our team will be in touch!

🧠The Importance of Leadership during Deployment

In anticipation to the second episode of the Lean Industry 4.0 - Operational Excellence meets Technology , we’re resharing the first featuring tons of insights on the importance of leadership during an industry 4.0 the deployments.

You can watch the conversation below.

📚What we’ve read this week

2024 State of Smart Manufacturing Report [Rockwell Automation]

The 9th Annual State of Smart Manufacturing Report from Rockwell Automation shares insights from their largest survey group yet, with more than 1,500 manufacturers in 17 countries describing their current state, biggest challenges, and goals for smart manufacturing in the year ahead.

While manufacturers face challenges such as inflation, high energy costs, and skills shortages, the survey results illustrate optimism and a readiness to embrace new technologies. Here are just a few highlights:

85% have already invested in or plan to invest in Generative AI

98% have a sustainability policy in place and energy management is rated as their top concern

94% expect to maintain or grow their workforce as a result of smart manufacturing technology adoption

Manufacturers Support Growth with Active Workforce Strategies [Deloitte & NAM]

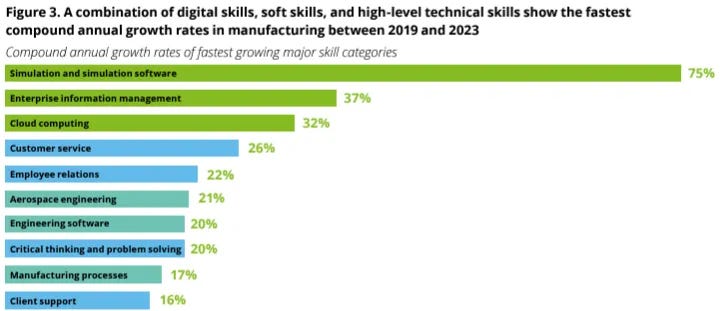

Deloitte & NAM surveyed 200+ US manufacturers, interviewed 10+ senior executives, and gathered secondary data on labor supply. Key findings:

Without addressing workforce challenges, up to 1.9 million of the 3.8 million needed jobs from now till 2033 may remain unfilled.

Pandemic-induced shifts have created new jobs, with growing demand for digital skills.

65% of manufacturers consider attracting and retaining talent their main business challenge.

90% are forming partnerships to improve employee attraction and retention, with an average of four partnerships each.

47% see apprenticeships, work-study programs, or internships as effective ways to increase industry interest.

Flexible work arrangements are favored by 47% for retention, including flex shifts and split shifts.

Supercharging Battery Manufacturing [Engineering.com]

A recent report by Benchmark Mineral Intelligence projects $300 billion investments in battery gigafactories by 2027. Gigafactories, sprawling across millions of square feet, aim to streamline battery production. Yet, scaling up faces hurdles:

Energy Density and Charging Speed: Balancing power, compactness, and quick recharging is crucial.

Scale-Up Time: It takes around seven years to commence and expand gigafactory operations, with long lead times for machinery.

Scrap Rate: Initial production may see up to 40% scrap, later stabilizing at around 15%.

Traceability: Upcoming regulations demand improved manufacturing process traceability.

To tackle these challenges, Siemens and Capgemini are partnering to offer integrated digital twins, enabling risk-free design and optimization of battery production lines.

Taking AI to the next level in manufacturing [MIT Technology Review]

Manufacturers rightly view AI as integral to the creation of the hyper-automated intelligent factory. They see AI’s utility in enhancing product and process innovation, reducing cycle time, wringing ever more efficiency from operations and assets, improving maintenance, and strengthening security, while reducing carbon emissions. Some manufacturers that have invested to develop AI capabilities are still striving to achieve their objectives. Research conducted by MIT Technology Review Insights found ambitions for AI development to be stronger in manufacturing than in most other sectors.

How data fuels the move to smart manufacturing [MIT Sloan School of Management]

Fueled by a combination of industrial data and artificial intelligence, a new era of smart and flexible manufacturing is underway. The technology promises to facilitate an environment where production can be seamlessly calibrated to pump out customized goods while factory floor equipment is maintained proactively to avoid costly downtime.

🎤 Upcoming Events

Returning to Greenville, SC, for the third year, the MX.0 Southeast event brings regional manufacturers together, equipping them with the necessary lessons and network to take the steps from Industry 3.0 to 4.0, and beyond. The M(anufacturing) X.0 agenda hosts national and regional manufacturers on stage who share practical, tried, and tested examples of ‘how to do’ digital transformation.

2024’s agenda brings case studies in change management, applying AI and Mixed Reality, rolling out Digital Twins, planning and scaling systems and processes, Cobots and Robots, tackling workforce problems, real-time data analytics, and much more.

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!