🚀 Shaping the Future - Issue 42

We’re starting our weekly showcase series of speakers at IME South, set to unfold in Charlotte, North Carolina from June 4-6, 2024.

🚨 Explore the Future of Manufacturing at IME South

Step into the Southeast's premier 6-in-1 expo and discover the latest innovations spanning medtech, packaging, automation, plastics, design, and processing. With over 3,000 attendees and 300+ leading suppliers, IME South is your gateway to meet industry leaders, explore cutting-edge solutions, and forge valuable connections in Charlotte.

📣 IME South Speaker Preview

We’re starting our weekly showcase series of speakers at IME South, set to unfold in Charlotte, North Carolina from June 4-6, 2024.

📌 Topic: Leveraging Kaizen for Future-Centric Industry 4.0 Advancements: A Paradigm Shift through Collaboration and Innovation

📝 Abstract: In today's competitive business landscape, organizations are increasingly turning to kaizen events as collaboration accelerators to not only advance the current processes, but envision the future process and generate advancements from that foundation. This presentation, titled "Leveraging Kaizen for Future-Centric Industry 4.0 Advancements: A Paradigm Shift through Collaboration and Innovation," delves into the strategic utilization of Kaizen as a powerful catalyst to accelerate collaboration and innovation in the successful implementation of Industry 4.0 advancements and cultural shifts that accompany the improvements. Often, automation initiatives are founded in the current state of a system and fall short of the maximum potential for step-function changes that occur by envisioning the future state of the process prior to implementing advancements. This presentation not only advocates for a paradigm shift, encouraging organizations to automate and advance processes based on the future reality rather than incremental improvements to the present, but it will outline the methodology to drive maximum innovation and implementation from the selected team. When the kaizen approach is taken, a team is able to truly evaluate what processes are value-adding to the future state, and likewise, what non-value-added processes can be reduced and eliminated, in conjunction with implementing automations and various cutting-edge advancements to the process. This is the power of building dynamic kaizen teams, utilizing a methodology that maximizes collaboration and creates rapid unprecedented innovation, and solidifying a culture of continuous progress.

👤 Presenter: Kirsten Gallagher, Owner/Founder Kaizen Ninja & KG CI Consulting

✍️ Bio: As the CEO of two rapidly growing organizations, Kirsten is known for the passion and enthusiasm she brings to process improvement. With a strong foundation in lean and six sigma, Kirsten has spent the majority of her professional career leading high-impact process improvement kaizen events that streamline organizations, improve team morale and lead to significant annual cost savings. She has become a highly sought-out facilitator in manufacturing, healthcare, and higher education across the country. Additionally, Kirsten provides experiential continuous improvement training to organizations and individuals who want to apply continuous improvement methodology and techniques to make a significant difference in their own organizations. Kirsten is also uniquely passionate about creating innovative tools for lean and six sigma implementations and has developed robust capacity analysis tools to integrate demand fluctuations, head count needs, equipment utilization and capacity, process step cycle times, and yields. She is continuously innovating by creating new tools, trainings and services to enhance the lean toolkit. In her free time, you will find Kirsten enjoys outdoor adventures including mountain biking, camping, and rock climbing. One of the most unique experiences that highlight’s Kirsten’s sense of adventure is the year-long RV trip that she took with her husband, two children, and 3 big dogs!

🧠The IT/OT Embrace: Closing the Divide

Last week’s discussion highlighted the importance of bridging IT (Information Technology) and OT (Operational Technology) teams for successful Industry 4.0 projects. Key obstacles include differing priorities and timelines, communication gaps, and misconceptions about each other's skills and objectives. To ensure synergy, early engagement, clear expectations, and ongoing communication are essential. By aligning priorities, understanding operational requirements, and fostering collaboration, organizations can overcome these challenges and harness the full potential of Industry 4.0 initiatives.

You can watch the full conversation below.

📚What we’ve read this week

Industry 4.0: Digital Transformation in Manufacturing [Leyton]

Industry 4.0 signifies the fusion of traditional manufacturing with advanced Information Technology (IT), ushering in a paradigm shift known as digital transformation. Key components include the Internet of Things (IoT) for real-time data collection and predictive maintenance, as well as real-time data analytics to optimize workflows and enhance quality control. This integration of IT enhances efficiency and agility, enabling streamlined supply chains, dynamic production scheduling, and data-driven decision-making through machine learning and AI. Challenges like cybersecurity and workforce skills require attention, but the trajectory of digital transformation in manufacturing promises continued innovation and collaboration among stakeholders to unlock its full potential.

Cloud Radar: Manufacturing Industry Report [Infosys]

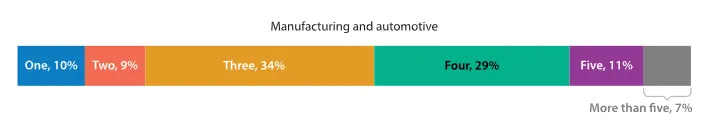

Some interesting highlights from Infosys Cloud Radar’s latest research report,

Research and development (R&D) and product development emerged as the highest-ranked use cases for cloud computing in the manufacturing and automotive industries.

34% of vehicle launches in 2023 experienced production delays, a nearly seven-fold increase from 5% in 2018

Carrier migrated its on-prem engineering tools, and the new system reduced costs by 40% and provided flexibility to scale up or down. It also offered a 50% performance improvement for specific use cases.

Manufacturers spend $30 million annually on cloud services, slightly less than the global average across industries. Regarding purchasing decisions, 43% are made in isolation by the IT department.

Volkswagen ‘The First Domino to Fall’ After Union Vote [Guardian]

Shawn Fain, president of the United Auto Workers (UAW), expressed optimism about the future of unionization across the US auto industry following a historic victory at a Volkswagen plant in Tennessee. This plant, the only non-union VW facility globally, voted overwhelmingly in favor of unionization, with 2,628 votes for and 985 against. This vote is part of a broader $40 million UAW campaign targeting 13 automakers with 35 non-union plants across the US. He expressed confidence that this victory would inspire similar outcomes at other plants, including an upcoming unionization vote at a Mercedes plant in Alabama, where workers have primarily led the campaign efforts. The UAW president criticized the anti-union stance of some corporate executives and politicians, particularly southern states' governors who have opposed the UAW's efforts, accusing them of siding with corporate interests over workers.

US Solar Manufacturers Call For New Solar-panel Tariffs [Canary Media]

First Solar and Qcells, two major U.S. solar panel manufacturers, are part of a coalition seeking new tariffs on imported solar panels from Southeast Asia, specifically Cambodia, Malaysia, Thailand, and Vietnam. The coalition argues that Chinese manufacturers' dominance and influence on global solar markets is due to unfair trade practices like dumping (selling products below cost) and illegal subsidies, which harm domestic manufacturers. They propose anti-dumping and countervailing duties to offset these practices, with suggested penalties ranging from 70% to 272% of the module cost, depending on the country. However, the move is controversial within the broader solar industry. While the manufacturers support the tariffs to protect domestic industry, project developers and various industry groups such as the Solar Energy Industries Association and American Clean Power Association oppose them. They argue that tariffs could increase market volatility and hinder the growth of the U.S. solar sector, which is crucial for achieving the Biden administration's carbon-free power generation targets by 2035.

The Revolutionary Impact Of Industry 4.0 [Forbes]

Industry 4.0, characterized by technologies like IoT, AI, cloud computing, and digital twins, revolutionizes industries by enabling predictive maintenance, remote monitoring and diagnostics, automatic software updates, asset tracking, automated fulfillment, and compliance monitoring. These technologies enhance operational efficiency, reduce downtime, and optimize production processes. Examples include Colgate-Palmolive's sensor-enabled preventive maintenance, Schlumberger's remote monitoring in oil rigs, and Lineas' asset tracking system. Challenges such as cybersecurity, ethical concerns, and workforce skills need ongoing attention, but Industry 4.0 fundamentally transforms production and management approaches.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!