🚀 Shaping the Future - Issue 43

Explore the Future of AI in Manufacturing with Mike Ungar at IIoT World Manufacturing Days.

📣 Explore the Future of AI in Manufacturing

Dear Industry 4.0 Club Members,

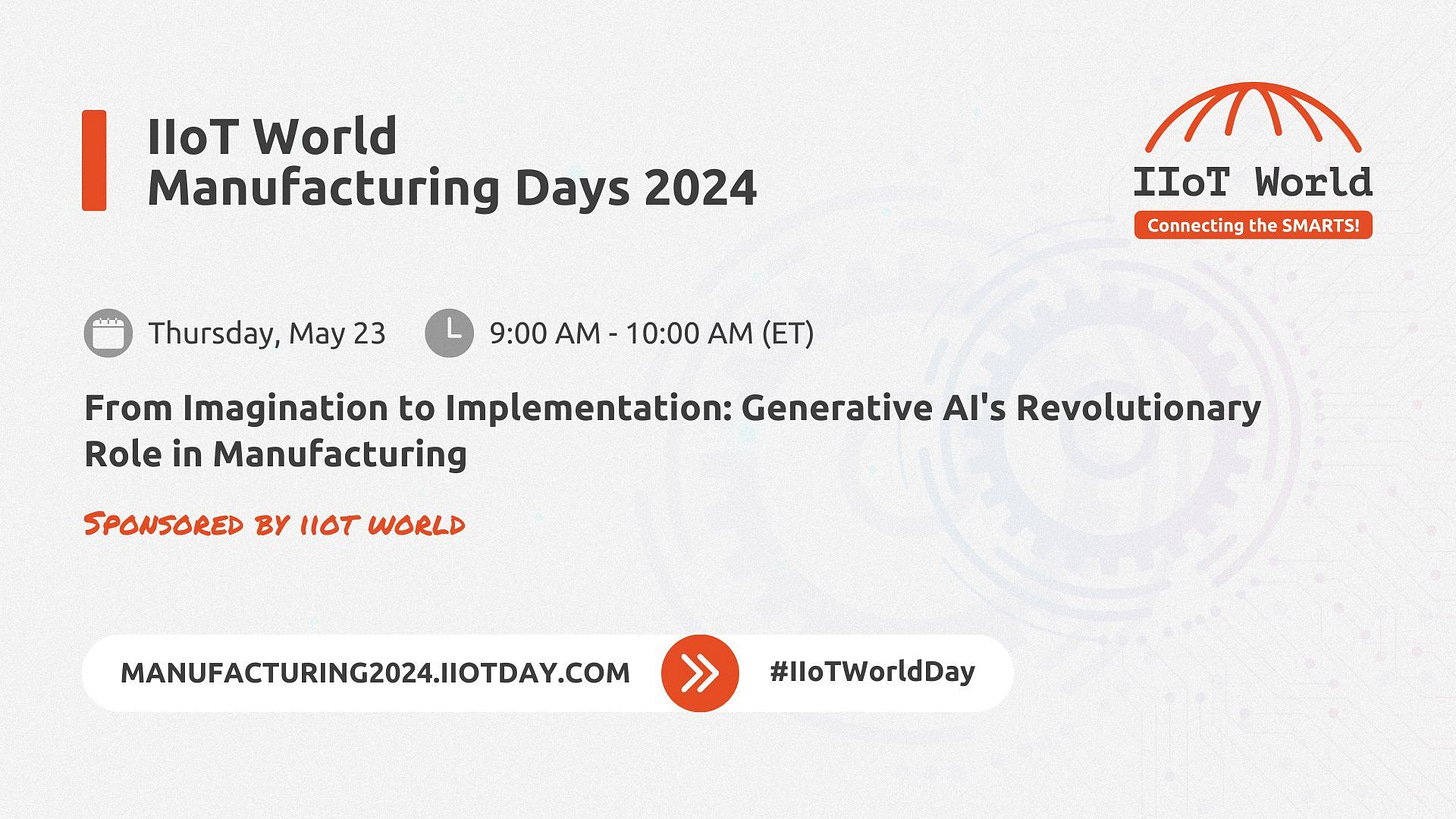

We're excited to invite you to an exclusive session at this year’s IIoT World Manufacturing Days, where our very own Mike Ungar will be moderating an insightful online panel titled 'From Imagination to Implementation: Generative AI’s Revolutionary Role in Manufacturing.'

Date/time of the session: May 23, 9 AM – 10 AM ET

Format: online panel discussion

Join Mike and a panel of distinguished experts as they explore real-world applications of generative AI that are redefining efficiency and innovation in our field. It’s a fantastic opportunity to connect with fellow innovators and thought leaders who are at the cutting edge of manufacturing technology.IIoT World offers free tickets by May 15 only.

🚨 Explore the Future of Manufacturing at IME South

Step into the Southeast's premier 6-in-1 expo and discover the latest innovations spanning medtech, packaging, automation, plastics, design, and processing. With over 3,000 attendees and 300+ leading suppliers, IME South is your gateway to meet industry leaders, explore cutting-edge solutions, and forge valuable connections in Charlotte.

📣 IME South Speaker Preview

We’re starting our weekly showcase series of speakers at IME South, set to unfold in Charlotte, North Carolina from June 4-6, 2024.

📌 Topic: Industrial AI: Cut Through The Hype and Get Real

📝 Abstract: All we hear about is data and AI, but what is actually happening in the real world? Delta Bravo founder and CEO Rick Oppedisano takes you behind the scenes of Industrial AI solutions with Nucor Steel, Rolls-Royce and more, sharing the “Holy Grail” of datasets used as the foundation for successful equipment reliability, quality and supply chain AI Use Cases. Rick will share a real-time, real life Industrial AI Copilot- and discuss why others have failed. As a bonus, Rick will share Delta Bravo’s AI Value Framework, used to identify, score and prioritize use cases with over 90 industry leaders since 2016. This is a can’t-miss presentation for anyone seeking to improve operations through better use of data.

👤 Presenter: Rick Oppedisano, CEO, Delta Bravo

✍️ Bio: Rick views manufacturing and civil infrastructure as critical ingredients in advancing human progress; his company, Delta Bravo Artificial Intelligence, uses AI to bring them to the next level. Rick founded Delta Bravo in 2016 in Rock Hill, SC and has built the company into an industry leader, serving customers like Rolls-Royce, AccuWeather, Nucor Steel, Continental, BMW, Nephron Pharmaceuticals and more. Delta Bravo’s work is well known and recognized through numerous industry awards for excellence in Machine Learning and Artificial Intelligence.

Rick was named a Global Top 25 Transformative Leader in Manufacturing by Smart Manufacturing Magazine in 2021 and has been featured on national television network A&E's American Entrepreneur series. Rick is a recognized expert in Industrial AI and its applications in quality, supply chain, equipment reliability, remanufacturing and circular economy planning. Rick has shared his perspective as a keynote speaker at the International Manufacturing Technology Show (IMTS), SME’s Smart Manufacturing Conference, International Manufacturing Expo (IME) South, South Carolina Automotive Manufacturers Association (SCMA), the Georgia Automotive Manufacturing Association (GAMA), the American Society for Quality (ASQ), and the Motor and Equipment Manufacturers Association (MEMA). Rick is very active in advancing artificial intelligence in his home state of South Carolina, serving on the Industry Board at the College of Charleston and most recently speaking at Governor Henry McMaster’s first inaugural Economic Summit in January of 2024.

Rick lives in Fort Mill, SC and enjoys spending time with his family, working on his classic BMW and watching New York Yankee baseball when they’re winning.

📚What we’ve read this week

Future-Proof Your Business With Smart Manufacturing [Forbes]

The Fourth Industrial Revolution, epitomized by Industry 4.0, heralds an era where data-driven technologies like AI, IoT, and digital twins are reshaping manufacturing. Leading companies are leveraging these innovations to enhance efficiency, reduce downtime, and optimize supply chains. However, the transition to smart manufacturing necessitates effective data governance and integration to harness the full potential of these technologies. With the imperative to adapt or risk obsolescence, manufacturers must prioritize digital transformation and invest in mastering data management to stay competitive in a rapidly evolving landscape.

How Taiwan is shaping an AI-fuelled Industry 4.0 revolution [BBC]

Taiwan stands at the forefront of the Fourth Industrial Revolution, showcasing its prowess in innovation across various sectors. Spearheaded by companies like Onyx Healthcare, Advantech, and Tongtai, Taiwan excels in cutting-edge technologies such as AI-driven healthcare solutions, edge computing systems for data management, and advanced manufacturing tools like the TMS-2500 5-axis multi-tasking turning centre. With a commitment to AI advancement and sustainability, Taiwan not only leads in global competitiveness but also envisions a future where innovation and collaboration drive positive change on the international stage, embodying a culture of freedom, experimentation, and invention.

China’s Electric Cars Keep Improving, a Worry for Rivals Elsewhere [NY Times]

Chinese automakers are driving innovation in the electric vehicle (EV) sector, spearheading a new era of more significant, technologically advanced cars poised to outpace global rivals. With 71 new battery-electric models to hit the market this year, China's automotive landscape is profoundly transforming. These next-gen EVs boast taller hoods for a bold aesthetic, enhanced storage capacity, and improved braking thanks to larger tires. Moreover, manufacturers prioritize passenger comfort with thicker, more comfortable seats, while advancements in battery technology enable faster recharging and increased power. Central to China's EV dominance are breakthroughs in battery technology, exemplified by CATL's latest battery boasting a 10-minute charge for a range of 370 miles. Moreover, advancements in battery efficiency allow for smaller batteries, freeing up interior space for enhanced passenger comfort and larger back seats with increased legroom. Chinese automakers also redefine automotive design aesthetics, opting for larger, more luxurious front ends and embracing sharper, edgier designs. This departure from lightweight aluminum in favor of steel alloys enables cost-effectiveness without compromising visual appeal. While the emphasis on electric propulsion continues to grow, Chinese manufacturers are attentive to consumer preferences, offering plug-in hybrids alongside pure electric options. Looking ahead, Chinese EVs are set to penetrate the lucrative U.S. market, with companies like Geely exporting models like the Polestar 2 despite facing tariffs. This strategic expansion underscores China's ambition to assert dominance beyond its borders, challenging established players and reshaping the future of the automotive industry.

Intel’s $28 Billion Comeback: Inside Ohio [Bloomberg]

Ohio One represents Intel's most ambitious endeavor. CEO Patrick Gelsinger envisions it as the world's largest chip factory, signaling Intel's commitment to technological advancement and economic resurgence. Gelsinger emphasizes the project's critical role in America's economy and national security, stating, "I just view this as existential to our economy, to our national security." The company has pledged $28 billion to build Ohio One, aiming to manufacture state-of-the-art chips crucial for smartphones and AI technology. Politicians, including President Joe Biden, have lauded the Ohio One project, positioning it as a centerpiece of the nation's economic policy. The US government has pledged significant financial support, with a $19.5 billion subsidy package under the Chips and Science Act. Intel's Ohio project comes amid the company's efforts to reclaim its technological leadership in the face of stiff competition and financial challenges. Intel's struggles in recent years, including declining market share and manufacturing setbacks, have underscored the urgency of its Ohio venture. Gelsinger acknowledges the difficulties ahead, describing the endeavor as "hard, multiyear, heavy, expensive," but expresses confidence in Intel's ability to succeed, noting, "we've done it before." However, Ohio One's success hinges on Intel's ability to secure major clients and compete with industry rivals like TSMC and Samsung.

Tesla Shrinks its Gigacasting Manufacturing Ambitions [Verge]

Traditionally, automakers assemble underbodies from numerous individual parts. However, Tesla sought to revolutionize this process by utilizing giant presses to die-cast large sections, aiming for a fully integrated underbody. This approach aimed to streamline manufacturing and drastically reduce costs. Tesla also introduced the "unboxed" manufacturing process, in which parts are assembled separately in dedicated areas before final integration, promising accelerated production and cost reductions. However, Tesla's ambitious plan has been postponed amidst declining sales and profits. The company has reverted to its existing manufacturing process, which is used for the Model Y and Cybertruck, where the underbody is composed of three sections: two gigacasted front and rear sections and a mid-section made from aluminum and steel, housing the battery. The company's Q1 report suggested that next-generation models would leverage new and existing platforms, potentially sharing manufacturing lines with current vehicles.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!