🚀 Shaping the Future - Issue 44

We're excited to invite you to an exclusive session at this year’s IIoT World Manufacturing Days, where our very own Mike Ungar will be moderating an insightful online pane.

📣 Explore the Future of AI in Manufacturing

Dear Industry 4.0 Club Members,

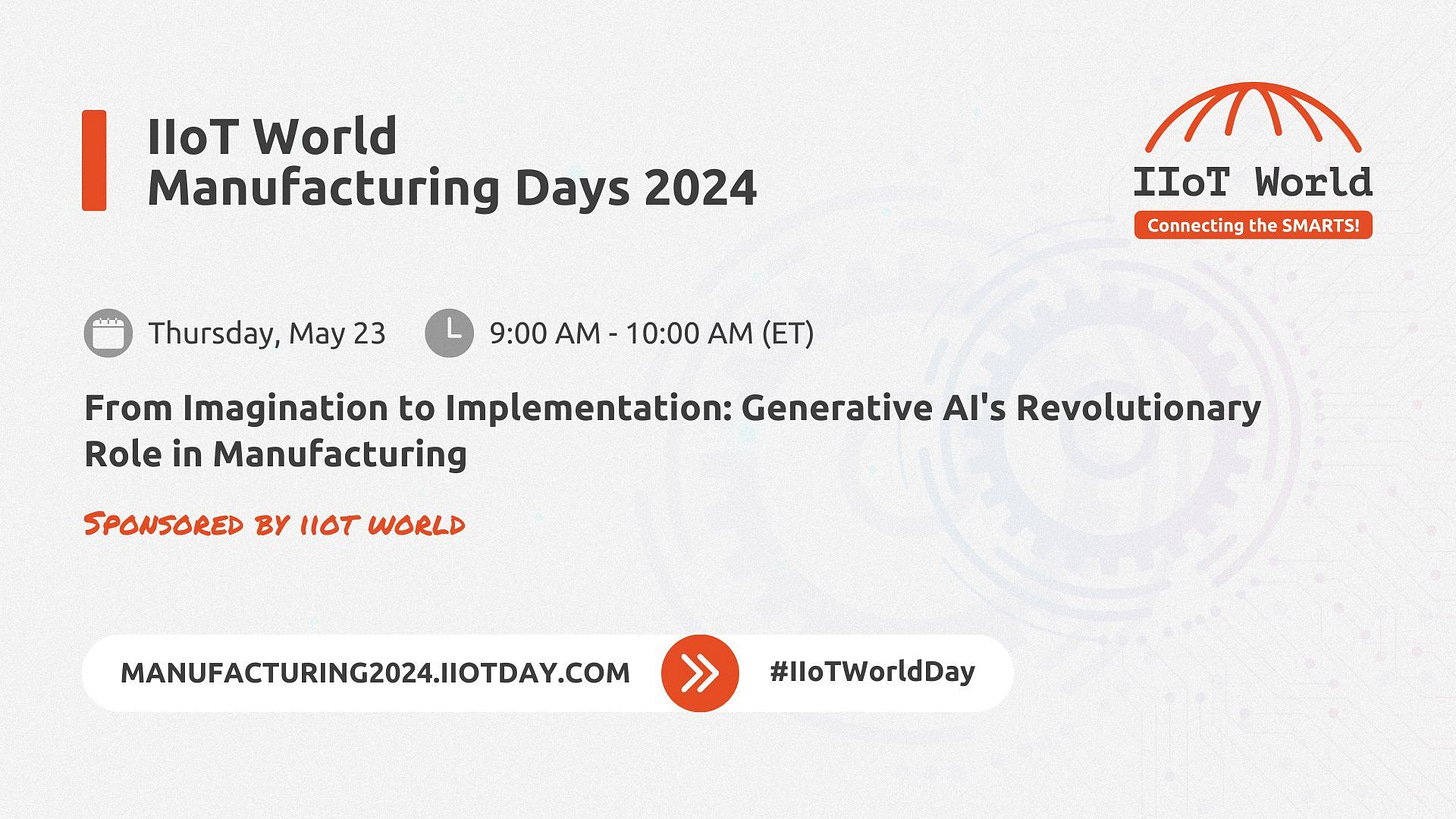

We're excited to invite you to an exclusive session at this year’s IIoT World Manufacturing Days, where our very own Mike Ungar will be moderating an insightful online panel titled 'From Imagination to Implementation: Generative AI’s Revolutionary Role in Manufacturing.'

Date/time of the session: May 23, 9 AM – 10 AM ET

Format: online panel discussion

Join Mike and a panel of distinguished experts as they explore real-world applications of generative AI that are redefining efficiency and innovation in our field. It’s a fantastic opportunity to connect with fellow innovators and thought leaders who are at the cutting edge of manufacturing technology. IIoT World offers free tickets by May 15 only.

🚨 Explore the Future of Manufacturing at IME South

Step into the Southeast's premier 6-in-1 expo and discover the latest innovations spanning medtech, packaging, automation, plastics, design, and processing. With over 3,000 attendees and 300+ leading suppliers, IME South is your gateway to meet industry leaders, explore cutting-edge solutions, and forge valuable connections in Charlotte.

🧠Growing Your Business through Local Sourcing

Last week’s episode highlighted the balance manufacturers must strike between strategic priorities and day-to-day operational challenges. The panel touched on sustainability and energy use, noting that while strategic, they are often secondary to immediate concerns such as labor shortages. With the growing pressure from clients for transparency in environmental, social, and governance (ESG) practices, the emphasis on sustainability has markedly increased over the past few years.

You can watch the full conversation below.

👩🏭IoT Adoption by OEMs

In last week’s discussion on applied research and manufacturing, shifted to the challenges manufacturers face in adopting data-driven cultures. Key obstacles include employee resistance to new technologies and the need to upgrade outdated machinery. Both Marcel and Tim emphasized the importance of addressing human factors and integrating advanced capabilities into existing processes.

The term "stack solution" was clarified as a multi-layered approach involving various components from different vendors to meet diverse manufacturing needs. Despite the complexity, there's no single vendor capable of providing a comprehensive solution for all facets of manufacturing. Instead, companies must navigate multiple solutions to achieve an integrated system, ensuring compatibility and efficient operation across various platforms and technologies.

You can watch the full conversation below.

📚What we’ve read this week

The Impact of Generative AI in Manufacturing at Hannover Messe 2024 [AWS]

A report from Capgemini reveals that a significant portion of manufacturers, totaling 100%, are exploring or implementing generative AI, with 55% investigating its potential and 45% engaging in pilot projects. At Hannover Messe 2024, AWS highlighted these advancements, showcasing over 25 demonstrations of generative AI. Examples include:

Tulip combined no-code apps, AI, and edge connectivity in its frontline operations suite to digitally transform processes faster through guided operations, production tracking, and real-time operational visibility.

Bosch showcased their digital twin solution for optimizing critical asset performance through multi-sensor data, physics-based AI algorithms, and prescriptive asset management combining sensing, insights, and automation.

MongoDB showcased a demo combining real-time telemetry data collection, vector search for acoustic diagnosis, and generative AI using Amazon Bedrock to provide users with real-time natural language reports on device status.

KONE uses Amazon Bedrock to empower field technicians with a generative AI-driven Assistant, leveraging vast libraries of technical documentation to enhance customer service.

Merck & Co. applies generative AI to reduce false rejects in pharmaceutical manufacturing by over 50%. By generating synthetic data, Merck enhances its ML models’ ability to identify genuine defects.

Vivix Vidros Planos leverages a Virtual Engineer powered by Mendix and Amazon Bedrock to accelerate new technicians' onboarding and training process.

IEA’s Advancing Clean Manufacturing Report

The IEA’s annual report highlighting the investment in clean technology manufacturing is back! Some key highlights:

Clean technology investment was approximately $200 billion in 2023, growing by more than 70% relative to 2022. Investments in solar PV and battery manufacturing plants led the way, accounting for more than 90% of the total in both years.

China accounted for three-quarters of global investments in clean technology manufacturing in 2023, down from 85% in 2022, as investment in the United States and Europe grew strongly – particularly for battery manufacturing.

China alone accounts for over 80% of global solar PV module manufacturing capacity and 95% of wafers.

About 40% of the investments in 2023 were for facilities expected to be operational in 2024, with nearly 70% of these investments directed towards battery manufacturing facilities.

The main upfront cost contributing to overall production costs is the capital expenditure to set up and the associated financing costs. For solar PV, wind, and battery manufacturing, facilities in the United States and Europe are typically 70% to 130% more expensive per unit of output capacity than those in China before accounting for the cost of capital between regions.

Annualized capital expenditure amounts to just 15% to 25% of the total cost of producing solar PV modules, with a cost of capital of 8%. The proportions are similar for batteries (10-20%), wind turbines, and heat pumps (2-10%) and somewhat higher for alkaline electrolyzer stacks (15-30%).

How Manufacturers Are Using Artificial Intelligence [NAM]

Here are some highlights from the National Association of Manufacturers detailing use cases for artificial intelligence in manufacturing and case studies of how manufacturers are already implementing AI technologies.

As of October 2023, 74% of surveyed manufacturers had invested or planned to invest in machine learning. Respondents noted a wide range of uses for AI in their operations, the top three of which were manufacturing and production, inventory management, and quality operations/R&D.

“Hitachi is focused on applying AI, machine learning, and related technologies to address real-world challenges in industrial and societal domains. Functional areas include maintenance and repair, operations optimization, quality assurance, safety management, supply chain management, and automation and control. The goal is end-to-end optimization of key industrial processes”— Chetan Gupta, the Hitachi Advanced AI Innovation Center GM.

Almost 80% of MLC survey respondents had invested in or planned to invest in vision systems, and 50% stated that predictive maintenance is a crucial AI application in their operations.

47% of surveyed manufacturers plan to deploy more customer-facing AI tools in the next two years.

21% of surveyed manufacturers already use AI for their supply chain management, and 60% plan to deploy it in the next 12–24 months.

2024 State of DIY Industrial Automation Report [Vention]

Here are some highlights from one year of data on manufacturers adopting and using Vention’s Manufacturing Automation Platform (MAP).

Small and medium manufacturers were the leading purchasers of automation systems on MAP in 2023, accounting for 48% and 17%, respectively. However, due to more challenging economic conditions, there was a 12% decline in purchases by small manufacturers (60% in 2022 vs. 48% in 2023)

Enterprise-sized manufacturers weren’t just the biggest adopters overall. They also outdid themselves, realizing more projects this year than last—an average of 4.9 in 2023, compared to 4.1 in 2022.

When comparing industries, Fulfillment, Distribution, & Retail realized the highest number of projects on MAP, followed by Aerospace & Defense, and Metrology & 3D Scanning.

In 2023, the MAP's most deployed robot cell application was Robot Pedestals & Bases, at 19.3% of deployments. This was followed by Pick & Place (16.6%), Robotic Tending Cells (12.4%), and Cobot Palletizers (12.4%)

Looking at applications, in 2023, machine-tending applications recorded the highest speed of project realization

Made in the USA: Defense companies tense as Congress pressures them to buy domestic [Defense One]

If adopted, the bill would require the Pentagon to create a plan—from budget to civilian needs—to replenish the National Defense Stockpile for a prolonged national emergency. Additionally, the panel expressed disappointment in the Navy’s “slow” progress to adopt “durable devices and technologies designed to operate in remote regions with limited network connectivity” as part of its digital supply chain efforts.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!