🚀 Shaping the Future - Issue 45

Step into the Southeast's premier 6-in-1 expo and discover the latest innovations spanning medtech, packaging, automation, plastics, design, and processing.

🚨 Explore the Future of Manufacturing at IME South

Step into the Southeast's premier 6-in-1 expo and discover the latest innovations spanning medtech, packaging, automation, plastics, design, and processing. With over 3,000 attendees and 300+ leading suppliers, IME South is your gateway to meet industry leaders, explore cutting-edge solutions, and forge valuable connections in Charlotte.

📣 IME South Speaker Preview

We’re starting our weekly showcase series of speakers at IME South, set to unfold in Charlotte, North Carolina from June 4-6, 2024.

📌 Topic: Lessons Learnt from Applying Smart Manufacturing to Small & Medium Manufacturers

📝 Abstract: More than 95% of the manufacturing sector in most global manufacturing economies are comprised of Small & Medium Manufacturers (SMMs). The penetration of Smart Manufacturing methods and principles over the last decade amongst the said SMMs has been abominably low. This begs the question – how is Industry 4.0 a revolution if 95% of the industry does not embrace it? This paper examines the barriers of entry for SMMs to embark on a Smart Manufacturing journey and provides some solutions for breaking the said barriers. The presentation will mainly share the learnings and the collective experience of implementing Smart Manufacturing in about 250+ SMMs across multiple use cases.

👤 Presenter: Ananth Seshan, CEO, 5G Technologies Ltd.

✍️ Bio: Dr. Ananth Seshan is the CEO of 5G Technologies Ltd., Canada, that specializes in Industry 4.0 technologies, AI and smart manufacturing solutions. The company has operations in Canada, USA, Mexico and India. Ananth has been helping Fortune 100 organizations worldwide for the last three decades in the areas of robotics, automation, and of late, AI & digital manufacturing. He is a member of the Board of Directors of MESA International. He was an invited member of a Special Task Force set up by Industry Canada to explore the viability of applying advanced manufacturing technologies as a strategy to build competitive advantage in the Canadian manufacturing sector. Over the last three years he has been an evangelist for the application of Industry 4.0 technologies using advanced AI technologies to Small and Medium Industries (SMEs). In particular, he has been involved in the ideation of 200+ successful implementations of Industry 4.0 solutions to the SME sector to date. He has been actively collaborating with the National Research Council, Canada, Asian Productivity Organization, Japan, Center for Industry 4.0 (C4I4), India, MESA-Africa and National Productivity Council, India, to promote Smart manufacturing to Small and Medium Enterprises in these respective jurisdictions.

Ananth received his Ph.D from the University of Toronto on 1992 for developing “common-sense” reasoning in robotic mechanisms after completing his Masters in Robotics & Automation from the Indian Institute of Technology, Madras in 1988. He has developed two online courses on Smart Manufacturing and has been recently invited to write a text book on the practice of Predictive Maintenance 4.0. He has been an invited keynote speaker in many international forums on manufacturing automation and has won several awards for innovation and entrepreneurship.

🧠Leveraging Kaizen for Future Centric I40 Advancements

The last Fireside Chat emphasized the transformative power of Kaizen events and Industry 4.0 advancements in driving significant process improvements. Kaizen, a Japanese term for "continuous improvement," encourages setting ambitious goals that challenge teams to think innovatively. Aiming for 25-30% improvement goals over a five-day period, often exceeding these targets and achieving results that dramatically shift both team and leadership mindsets.

You can watch the full conversation below.

📚What we’ve read this week

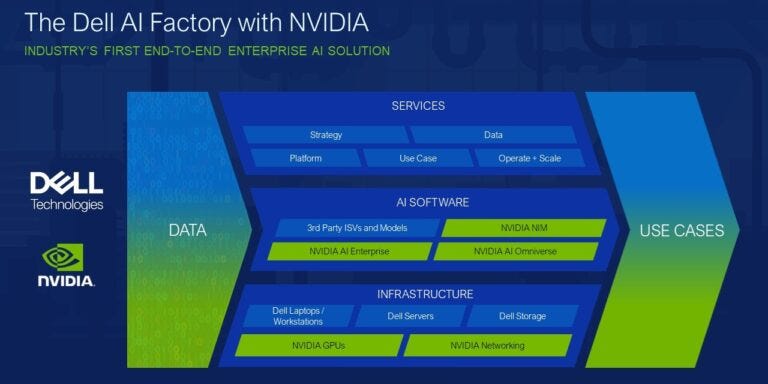

The Dell AI Factory with NVIDIA [Dell]

Organizations seek to capitalize on faster time-to-value from AI-based operations and innovation going into production. The Dell AI Factory enables organizations to benefit from our advanced AI capabilities earned through years of investment and experience in AI, our extensive global experience and comprehensive knowledge in deploying AI at scale for our customers. The Dell AI Factory with NVIDIA, a production example of the Dell AI Factory, delivers an integrated, comprehensive framework of leading solutions, platforms, software and services closely developed with NVIDIA to assist enterprises in building and deploying repeatable outcomes with their custom AI factories across their organization from data center to devices to edge to cloud.

IEA’s Advancing Clean Manufacturing Report

The IEA’s annual report highlighting the investment in clean technology manufacturing is back! Some key highlights:

Clean technology investment was approximately $200 billion in 2023, growing by more than 70% relative to 2022. Investments in solar PV and battery manufacturing plants led the way, accounting for more than 90% of the total in both years.

China accounted for three-quarters of global investments in clean technology manufacturing in 2023, down from 85% in 2022, as investment in the United States and Europe grew strongly – particularly for battery manufacturing.

China alone accounts for over 80% of global solar PV module manufacturing capacity and 95% of wafers.

About 40% of the investments in 2023 were for facilities expected to be operational in 2024, with nearly 70% of these investments directed towards battery manufacturing facilities.

The main upfront cost contributing to overall production costs is the capital expenditure to set up and the associated financing costs. For solar PV, wind, and battery manufacturing, facilities in the United States and Europe are typically 70% to 130% more expensive per unit of output capacity than those in China before accounting for the cost of capital between regions.

Annualized capital expenditure amounts to just 15% to 25% of the total cost of producing solar PV modules, with a cost of capital of 8%. The proportions are similar for batteries (10-20%), wind turbines, and heat pumps (2-10%) and somewhat higher for alkaline electrolyzer stacks (15-30%)

Emerging Resilience in the Semiconductor Supply Chain

A new report by the Semiconductor Industry Association (SIA) and BCG on the semiconductor supply chain forecasts significant improvements in the resilience of the supply chain in both the U.S. and globally in the coming years. Some key highlights:

America’s projected 203% increase in fab capacity from 2022 to 2032 is world-leading, a stark difference from its modest 11% increase from 2012 to 2022.

The U.S. share of the world’s chip manufacturing capacity will increase from 10% in 2022—when the CHIPS and Science Act was enacted—to 14% by 2032, marking the first time in decades the U.S. has grown its domestic chip manufacturing footprint relative to the rest of the world.

The U.S. is expected to attract $646 billion in capital investments, more than one-quarter (28%) of the total $2.3 trillion global semiconductor investment.

The U.S. will gain fab capacity share in crucial technology segments, including leading-edge logic, DRAM memory, and analog. For example, the U.S. will gain new capabilities in advanced logic, growing its share from 0% to 28% by 2032.

How Manufacturers Are Using Artificial Intelligence [NAM]

Here are some highlights from the National Association of Manufacturers detailing use cases for artificial intelligence in manufacturing and case studies of how manufacturers are already implementing AI technologies.

As of October 2023, 74% of surveyed manufacturers had invested or planned to invest in machine learning. Respondents noted a wide range of uses for AI in their operations, the top three of which were manufacturing and production, inventory management, and quality operations/R&D.

“Hitachi is focused on applying AI, machine learning, and related technologies to address real-world challenges in industrial and societal domains. Functional areas include maintenance and repair, operations optimization, quality assurance, safety management, supply chain management, and automation and control. The goal is end-to-end optimization of key industrial processes”— Chetan Gupta, the Hitachi Advanced AI Innovation Center GM.

Almost 80% of MLC survey respondents had invested in or planned to invest in vision systems, and 50% stated that predictive maintenance is a crucial AI application in their operations.

47% of surveyed manufacturers plan to deploy more customer-facing AI tools in the next two years.

21% of surveyed manufacturers already use AI for their supply chain management, and 60% plan to deploy it in the next 12–24 months.

2024 State of DIY Industrial Automation Report [Vention]

Here are some highlights from one year of data on manufacturers adopting and using Vention’s Manufacturing Automation Platform (MAP).

Small and medium manufacturers were the leading purchasers of automation systems on MAP in 2023, accounting for 48% and 17%, respectively. However, due to more challenging economic conditions, there was a 12% decline in purchases by small manufacturers (60% in 2022 vs. 48% in 2023)

Enterprise-sized manufacturers weren’t just the biggest adopters overall. They also outdid themselves, realizing more projects this year than last—an average of 4.9 in 2023, compared to 4.1 in 2022.

When comparing industries, Fulfillment, Distribution, & Retail realized the highest number of projects on MAP, followed by Aerospace & Defense, and Metrology & 3D Scanning.

In 2023, the MAP's most deployed robot cell application was Robot Pedestals & Bases, at 19.3% of deployments. This was followed by Pick & Place (16.6%), Robotic Tending Cells (12.4%), and Cobot Palletizers (12.4%)

Looking at applications, in 2023, machine-tending applications recorded the highest speed of project realization

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!