🚀 Shaping the Future - Issue 46

Our weekly showcase series of speakers at IME South continues, the conference is happening this week in Charlotte, North Carolina from June 4-6, 2024.

🚨 Explore the Future of Manufacturing at IME South

Step into the Southeast's premier 6-in-1 expo and discover the latest innovations spanning medtech, packaging, automation, plastics, design, and processing. With over 3,000 attendees and 300+ leading suppliers, IME South is your gateway to meet industry leaders, explore cutting-edge solutions, and forge valuable connections in Charlotte.

📣 IME South Speaker Preview

Our weekly showcase series of speakers at IME South continues, the conference is happening this week in Charlotte, North Carolina from June 4-6, 2024.

📌 Topic: Keys to Establishing Transformative, Sustainable Analytics

📝 Abstract: In a typical, fast-paced manufacturing organization, data is plentiful but often not optimized for decision making. There are usually some superstar business analysts who find a way—despite the IT obstacles—to create meaningful charts and tables for management each month. Unfortunately, this is too often built on house-of-cards data which creates pain points for both the creators and the audience. How do manufacturers get out of the cycle of non-repeatable, unstable analytics and move into a sustainable, reliable flow of data, information and ultimately insights? How can they hope to tap into the latest advances in predictive analytics and AI when the data foundation isn’t even set? That’s what we will tackle in this engaging talk around the hard, yet rewarding work of enterprise analytics.

👤 Presenter: Shelly Kunkel, Senior Data Consultant, Snow Fox Data

✍️ Bio: Shelly Kunkle is a dynamic leader in the AI and data analytics space who has made a significant impact, specifically within the manufacturing industry. In her current position as a Senior Data Consultant at Snow Fox Data, she guides clients in establishing and refining Analytics Centers of Excellence, advancing machine learning and AI projects, and delivering expertise on top tech stack tools including Dataiku, Power BI, and Snowflake. Prior to this, Shelly had an extensive tenure at Michelin across various capacities, culminating as the Global Lead for Customer Data Analytics. During this time, she developed CRM analytics tools, employed AI for operational efficiencies, and advocated for data-centric strategies that markedly enhanced business processes and customer engagement. Her academic credentials from the Georgia Institute of Technology, paired with her hands-on experience in strategic data utilization, mark her as a pioneering force in leveraging analytics for substantial business value.

🧠Empowering your Workforce with Technology

The implementation of new technologies in workplaces can be a double-edged sword, either fostering a proactive safety culture or breeding distrust among employees, depending on the company's approach. Effective communication and trust are essential, as poorly handled introductions of technologies like robotics or video analytics can be perceived as invasive or job-threatening, leading to resistance and even sabotage.

Last week’s Lean Industry series was full of great insights on how to empower your workforce with technology. You can watch the full conversation below.

📚What we’ve read this week

Is Industry 4.0 Here? How AI is Transforming Manufacturing Today [Manufacturing Tomorrow]

Industry 4.0, defined by McKinsey as the era of intelligent cyberphysical systems, builds on advancements from previous industrial revolutions, integrating AI-powered analytics to unify operational data silos for improved efficiency, cost reduction, and enhanced human experience on factory floors. Differentiated by technological convergence, open innovation, and systemic remodeling, Industry 4.0 is evidenced by significant market adoption, with AI projected to see substantial growth in manufacturing. Companies like SparkCognition showcase transformative AI applications, including predictive maintenance, operational visibility, and data standardization, demonstrating substantial productivity improvements and cost reductions in sectors like aerospace.

How Canadian companies can embrace Industry 4.0 [PwC]

Industry 4.0 is revolutionizing manufacturing and other sectors by leveraging digital integration, AI, and machine learning to enhance value chain efficiency and decision-making. AI-driven analytics and machine learning are enabling manufacturers to respond to customer demand shifts, improve product quality, optimize inventory, and track supply chains. As these technologies mature, they will tackle more complex tasks and integrated processes. Southwestern Ontario is poised to lead this digital transformation in Canada, benefiting from its robust industrial base, academic institutions, and innovative companies.

Gaining Visibility Into Discrete Manufacturing Processes With MQTT [HiveMQ]

Discrete manufacturing, involving the production of distinct items such as automobiles and electronics, benefits from systems like CAD, CAM, ERP, and PLM for efficient operations. Critical processes include production planning, batch size optimization, and lead times, all enhanced by data visibility. The integration of Industrial IoT (IIoT) and MQTT technology, a lightweight messaging protocol, is transforming discrete manufacturing by enabling real-time data communication, scalability, efficient bandwidth usage, reliability, and enhanced security. This connectivity facilitates advanced data use cases like predictive maintenance and remote monitoring, ultimately boosting operational efficiency, reducing costs, and enhancing customer satisfaction.

Eight Common Supplier Management Mistakes and Risk Mitigation Options [Manufacturing MX.0 Insights]

Effective Supplier Management is crucial for business success, yet many organizations make common errors that can hinder performance and relationships. Key mistakes include not aligning Supplier Management with business strategy, lacking clear goals, inadequate training, insufficient supplier evaluation, over-reliance on single suppliers, poor performance monitoring, neglecting relationship management, and weak communication. Each mistake carries risks, such as inefficiencies, supply chain disruptions, and reduced supplier commitment. Mitigation strategies involve integrating Supplier Management with business objectives, developing strategic plans, investing in training, conducting thorough supplier evaluations, diversifying suppliers, implementing performance monitoring systems, fostering strong relationships, and improving communication. Thurman Co. offers support in enhancing Supplier Management practices through tailored solutions.

A Data & AI horror story #3 [Put People First in Data & AI- LinkedIn]

In the concluding article of the series on overcoming fear of data and AI in a medium-sized industrial company, we faced three potential outcomes. Version A depicts prolonged struggles and escalating costs leading to managerial intervention. Version B highlights a pivot to a more feasible use case, resulting in a successful demonstrator presented by the defect inspection team. Version C describes a unilateral switch to a new use case and a top-down push to implement it. The chosen conclusion is Version B, as it emphasizes collective decision-making, adaptability, and empowerment of the defect inspection team, fostering a collaborative and sustainable approach to integrating AI.

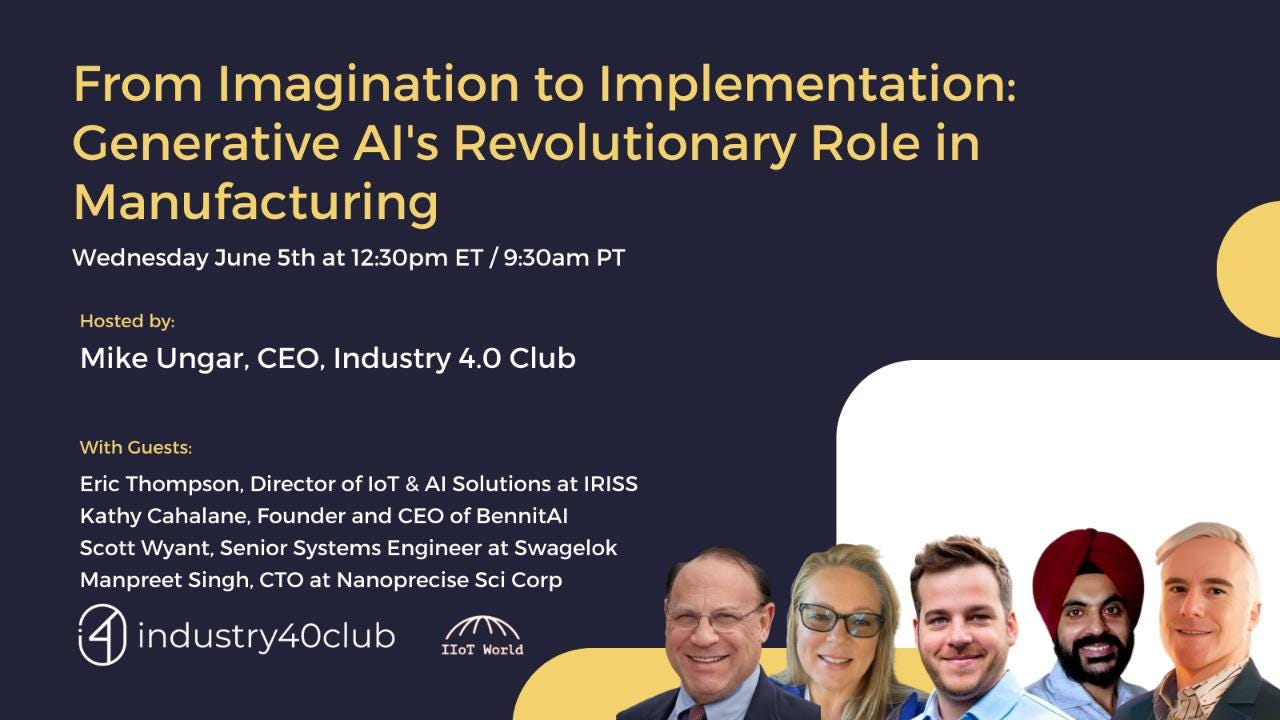

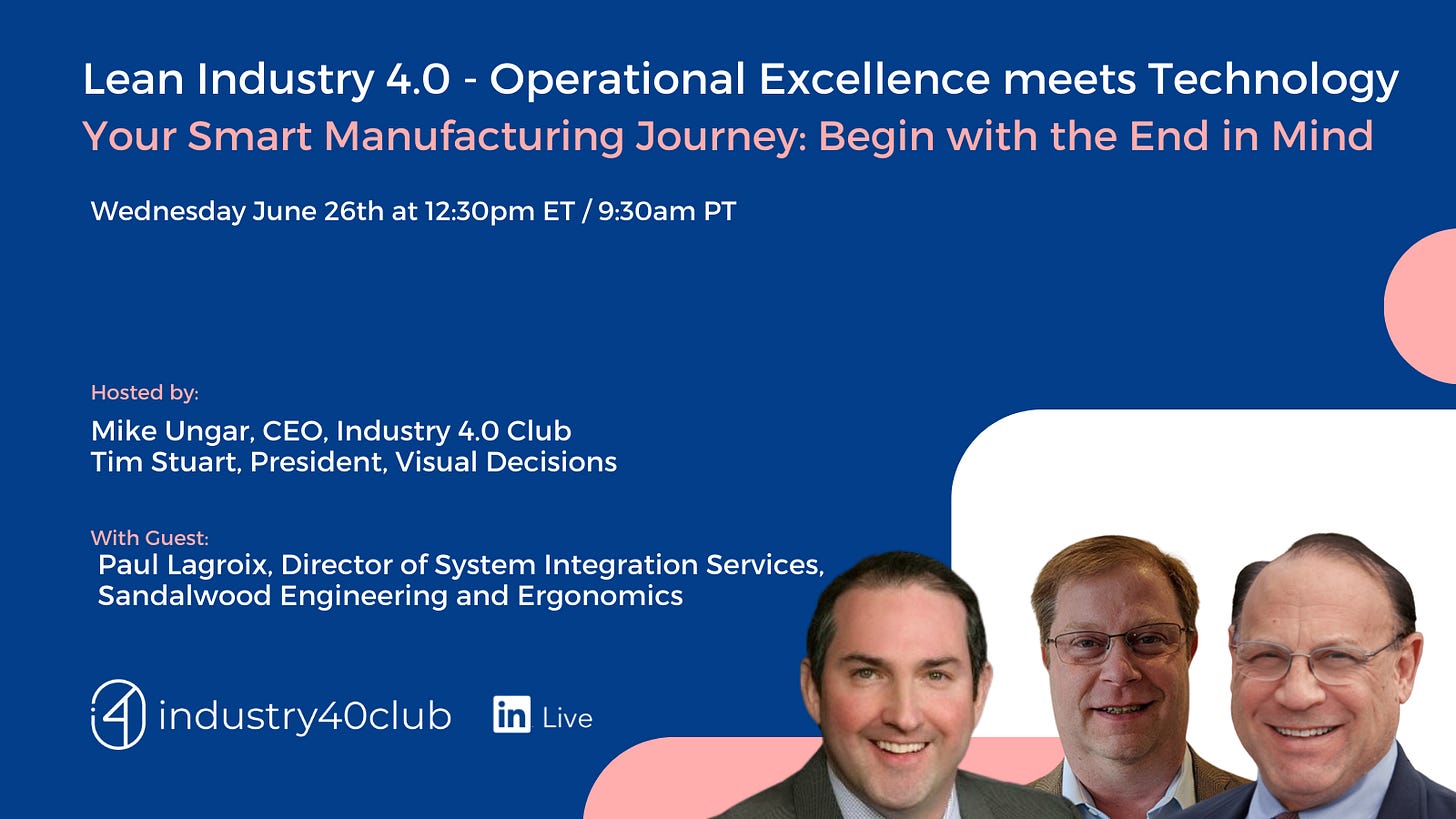

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!