🚀 Shaping the Future - Issue 47

To address the shortage of over 600,000 unfilled manufacturing jobs in the U.S., exacerbated by the pandemic and long-term recruitment issues, companies are enhancing their training programs.

🧠Generative AI's Revolutionary Role in Manufacturing

In the last Fireside Chat, the panel highlighted the potential of generative AI to optimize shop floor operations, enhance communication between machines and humans, and improve support functions such as engineering and maintenance.

Despite the clear benefits, the adoption of generative AI in manufacturing remains limited. The panelists called for increased awareness and critical evaluation of AI's capabilities, encouraging the industry to embrace these tools to drive efficiency and innovation. You can watch the full conversation below.

📚What we’ve read this week

Welcome to School. It's Actually a Factory [Bloomberg]

To address the shortage of over 600,000 unfilled manufacturing jobs in the U.S., exacerbated by the pandemic and long-term recruitment issues, companies like GE, Siemens, and GAF are enhancing their training programs. GE expanded its welding training at its Beavercreek, Ohio, plant to produce up to 48 welders annually, addressing a surge in demand from 10 to 31 welders. Siemens introduced a new training protocol at its Fort Worth, Texas, plant to bridge skills gaps for newcomers to manufacturing. GAF’s roofing academy, launched in 2020, has trained over 3,000 individuals, with around 1,600 successfully placed in jobs, partnering with organizations like the Job Corps and local entities to attract diverse candidates, including non-violent offenders.

Fictiv 2024 State of Manufacturing Report

Fictiv released its State of Manufacturing Report tracking perspectives on the economy, supply chain, AI, sustainability, and more. Here are some of the highlights:

AI and Hiring - 87% of respondents agree that implementing AI into manufacturing is "...vital to my company's future success." Notably, nearly half of companies say that AI has enabled them to reduce planned hiring, and 34% expect AI to impact hiring in the next two years.

New Product Innovation - The focus on increasing the speed of innovation (45%) remains high, and reports of barriers to innovation have decreased across the board. In fact, the number of respondents reporting no barriers (15%) more than doubled since last year to its highest level in four years.

Global Supply Chain - 86% of respondents say global tensions are long-term planning considerations. However, while it is still important for U.S. manufacturers to go onshore (66%), this trend has fallen since last year (77%), even as diversifying global manufacturing operations has increased this year.

Supply Chain Regionalization - Increasing U.S. manufacturing (on-shoring) remains the leading supply chain strategy for the third year (66%), yet it has fallen substantially since last year. At the same time, North American production (near-shoring) has increased again this year (53%).

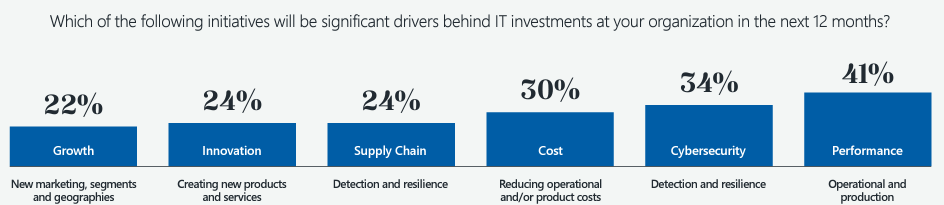

Rootstock 2024 State of Manufacturing Technology Survey

Rootstock released its State of Manufacturing Technology survey assessing how manufacturers view their digital transformation journeys. Here are some of the highlights:

Despite 90% of manufacturers utilizing some form of AI in their operations, the survey revealed there is a level of imposter syndrome when it comes to AI implementation and progress, with 38% reporting they feel behind their peers

Manufacturers show a positive outlook on digital transformation (63%), with the majority feeling they’re at least on par with peers (39%) or slightly ahead (24%).

Manufacturers anticipate significant negative impacts from current economic conditions. The top concerns were unreliable suppliers (39%) and decreased demand (36%).

Over half (51%) of manufacturers are planning to increase spending in this area (such as ERP, CRM, HCM, SCM, and finance), underscoring the importance of these digital tools for future growth.

Manufacturers leveraging Cloud ERP reported reduced overall costs (56%), improved IT security (46%), and enhanced business agility and resiliency (46%).

The Economics of Additive Manufacturing are Broken [TCT Opinion]

Industrial 3D printing, or additive manufacturing (AM), is hindered by high production costs and a lack of design expertise among engineers, restricting its use to niche applications and prototyping. Despite its flexibility, AM remains costly due to expensive materials and production processes, creating a cycle of high costs and limited adoption. To overcome these challenges, industry leaders should automate manufacturing processes to enhance efficiency and lower costs, integrate AM into more industrial workflows, and adopt machine utilization-based pricing models. China's competitive pricing and rapid AM adoption demonstrate the benefits of strategic investments in infrastructure and automation, crucial for realizing AM's potential in global manufacturing.

Watch This Space Here Come Generative Manufacturing Designs [Engineering]

InfinitForm is developing generative software designed to create usable and manufacturable parts, focusing on optimization for cutting tools rather than traditional roundabout methods. It allows users to specify cutting tool details, balancing production time and detail level, and outputs solid models instead of triangulated meshes. Shifting from an emphasis on 3D printing, InfinitForm prioritizes machinability and cost-effectiveness, leveraging advanced GPU hardware to rapidly optimize complex models. Initially offered as a cloud-based solution, InfinitForm will later release a local version to meet the security needs of industries like military and defense.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!