🚀 Shaping the Future - Issue 48

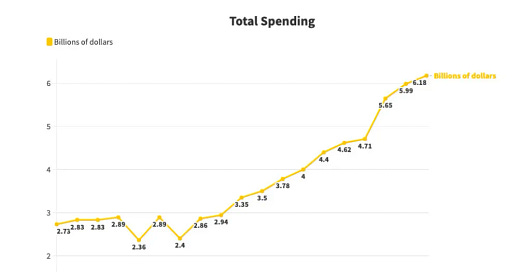

U.S. assembly plants are spending $6.18 billion on new equipment in 2024, an increase of 3 percent from the $5.98 billion projected to be spent in 2023.

🧠Operational Excellence meets Technology

Incorporating Data and AI into business processes involves more than just incremental changes; it requires a cultural shift and strategic innovation. Using digital and AI tools to automate data collection and analysis can significantly enhance lean processes, such as SMED, by providing real-time insights and streamlining improvements. Embracing these tools can foster a culture of continuous improvement and ensure companies stay competitive in the rapidly evolving Industry 4.0 landscape.

Mike and Tim had an insightful chat about how operational excellence meets technology. You can watch the full conversation below.

📚What we’ve read this week

2023 Manufacturing Capital Spending Survey [Assembly Magazine]

Here are some highlights from Assembly Magazine’s 28th Annual Capital Equipment Spending Survey:

U.S. assembly plants will spend $6.18 billion on new equipment in 2024, an increase of 3 percent from the $5.98 billion projected to be spent in 2023.

The Automotive industry will account for 63 percent of all spending next year and automotive assemblers will spend $7,786,111 on capital equipment next year, 4x the national average.

After accounting for more than 30 percent of total equipment spending in each of the past two years, machinery manufacturers (NAIC 333) will represent just 2 percent of spending in 2024.

The Midwest has traditionally been the epicenter of U.S. manufacturing, and next year will be no exception. The region will account for 52 percent of spending in 2024, more than any other part of the country and the most for the region since 2018.

“The world record of 500,000 units was exceeded for the second year in succession,” says Marina Bill, president of IFR and group vice president for robotics and discrete automation at ABB Inc. “In 2023, the industrial robot market is expected to grow by 7 percent to more than 590,000 units worldwide.”

We expect sales of six-axis robots, SCARAs, grippers, and other robotic technology to increase 11 percent, from $720 million in 2023 to $799.4 million in 2024.

The Manufacturing Shift Is Affecting Shipping [QZ]

The global shipping industry faces collapsing container rates, a freight recession, and overcapacity. However, intra-Asia shipping is a bright spot, driven by manufacturers diversifying their supply chains. Vietnam, in particular, has become a critical node in global trade flows due to surging foreign investment and increased manufacturing activity. Direct shipping routes between Vietnam and the US have almost doubled, and Vietnam's ranking in countries with direct shipping services to the US has sharply risen. The country's maritime transport industry is experiencing remarkable growth, with an 83% increase in scheduled deployed capacity between the US and Vietnam from 2019 to 2023. While China remains central to global trade, the trend of diversification is evident as Vietnam becomes an extra call in shipping routes, confirming Asia's role as the manufacturer of the world. For Vietnam to fully capitalize on increased intra-Asia shipping, infrastructure investment, possibly from China, is essential to enhance port efficiency and connectivity. China has shown interest in port investments across Asia, viewing it as a form of "port diplomacy" to gain global leverage.

Watch This Space Here Come Generative Manufacturing Designs [Engineering]

Infinitform aims to create generative software capable of designing usable and manufacturable parts. Unlike traditional generative design software, InfinitForm focuses on optimizing parts with cutting tools in mind, a departure from the roundabout methods used by existing software. InfinitForm allows users to specify the number of axes and size of cutting tools, offering a tradeoff between production time and level of detail. Notably, the software outputs solid models, distinguishing it from other shape optimizers that produce triangulated meshes. Michael's decision to prioritize machinable parts reflects a shift from the previous emphasis on 3D printing. Despite the hype around lightweight parts produced by generative design, Michael recognizes the importance of manufacturability and cost-effectiveness. The optimization process, powered by advances in hardware like GPUs, can now happen rapidly, with complex models solved in seconds. InfinitForm plans to release its software initially as a cloud-based solution, with a local option to follow. This local solution will cater to industries like military and defense, which require security measures that preclude cloud usage.

Innovate or die in data and AI! [Put People First in Data & AI]

Incorporating Data and AI is a disruptive, not incremental, change as discussed in Clayton M. Christensen's "The Innovator's Dilemma." The book explains how established companies often fail to adopt disruptive technologies because they focus on immediate needs rather than future opportunities, which new firms can exploit to overtake them. For successful AI transformation, companies should consider creating dedicated teams separate from core IT to foster innovation. Ignoring disruptive AI technologies risks allowing new competitors to capture emerging markets and eventually threaten established businesses. Therefore, it's crucial for companies to innovate proactively in the Data and AI landscape to secure their future.

Don't become slave of data & AI! [Put People First in Data & AI]

While Data and AI, including generative AI, are powerful technologies, it's essential to avoid becoming blinded by the hype. Companies should not focus solely on technology without considering the needs and maturity of their people, shift all investments to generative AI at the expense of critical data foundations, rely exclusively on a single model like ChatGPT without a backup, or think AI is only about generative AI, neglecting other valuable AI technologies. Instead, businesses should prioritize people’s needs, build AI solutions progressively, and maintain flexibility by developing modular solutions. This approach ensures a balanced, effective, and resilient AI integration.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!