🚀 Shaping the Future - Issue 54

Last week’s chat revolved around the importance of aligning organizational culture with digital transformation initiatives for successful IT and OT convergence.

🧠A Recipe for Digitalization Success

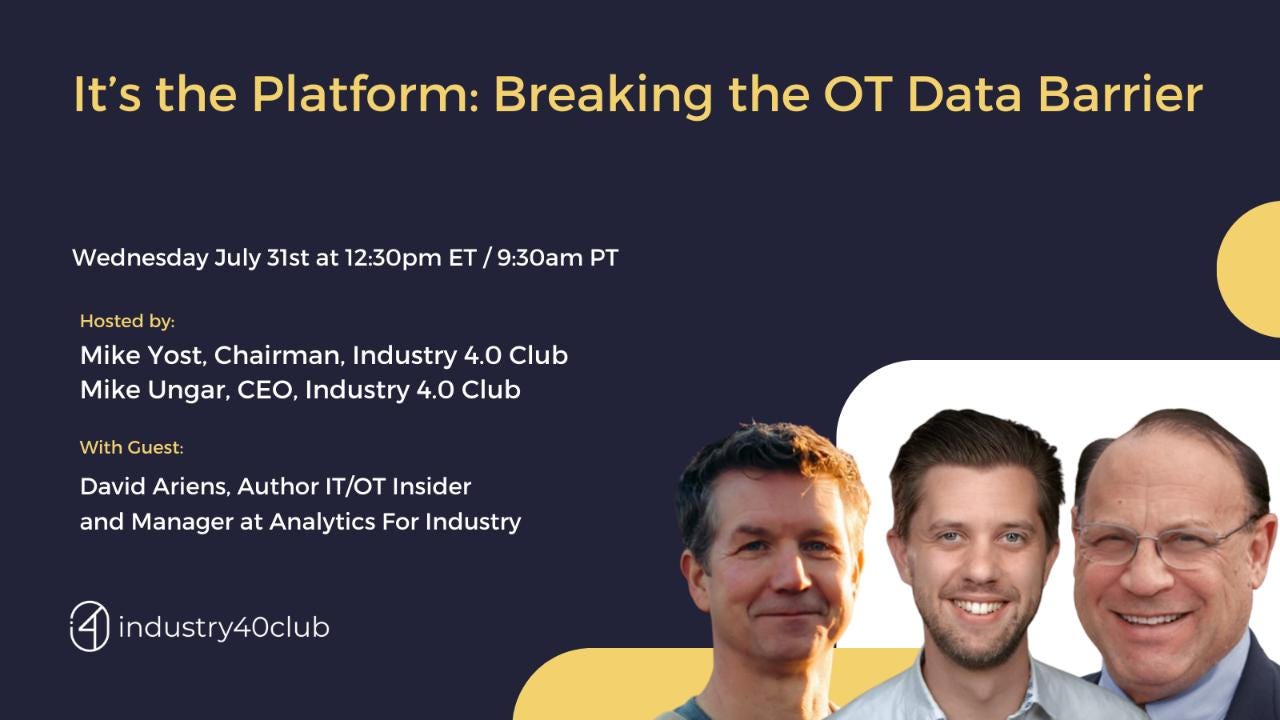

Last week’s chat revolved around the importance of aligning organizational culture with digital transformation initiatives for successful IT and OT convergence. The panel emphasized the need to apply Industry 4.0 thinking to solve Industry 4.0 problems, rather than relying on traditional Industry 2.0 management approaches that prioritize hierarchical decision-making and production efficiency. This shift is crucial for fostering innovation and adaptability within organizations, especially in the face of rapid technological advancements and changing market dynamics. You can watch the full conversation below.

📚What we’ve read this week

The State of Production Health 2024 [Augury]

Augury released its second annual State of Production Health report. Below are some of the key insights from the report:

83% of industrial leaders are investing more in AI in 2024, up from 63% in 2023.

Twice as many respondents say they can quantify benefits for machine health/downtime (36% vs. 16%), and three times as many report impact to process health/maximizing yield and capacity (40% vs. 13%).

While manufacturers rank the supply chain as the top production obstacle (cited by 25% of respondents) and a significant AI use case (43%), industrial leaders’ lowest-ranked objective for leveraging AI remains.

Most (91%) industrial leaders worry that retiring veterans exacerbate the knowledge gap in manufacturing.

"Though AI has started proving its effectiveness, nine out of ten industrial leaders say that just 11-50% of their AI pilots have reached scale."

Tracking North American EV Battery Factory Construction [Techcrunch]

An excellent breakdown from Techcrunch on the investment from automakers and battery manufacturers resulting from the IRA. Specifically under Section 45X, where the production of battery cells qualifies for a credit of $35 per kilowatt-hour of capacity, and the production of battery modules qualifies for $10 per kilowatt-hour. Together, automakers and battery manufacturers promise to deliver an annual capacity of close to 1,200 gigawatt-hours before 2030 if each factory reaches maximum capacity. That’s roughly enough batteries for 18 million EVs, based on previous Tesla predictions that say about 100 GWh capacity can power around 1.5 million EVs.

Improving Productivity in Low-Volume, High-Complexity Mfg [McKinsey]

Industrial companies producing low-volume, high-complexity (LV/HC) products, such as passenger airplanes, paper machines, forklifts, and construction cranes, face unique manufacturing challenges. These products, typically customized and produced in small quantities (between 10 and 10,000 units annually), are critical to customers' missions and come with high costs due to component expenses, stringent quality requirements, and the need for specialized manufacturing facilities and equipment. Labor costs are also significant, as fewer tasks can be automated. In commercial aerospace, the sector most disrupted by the pandemic, the demand increase has exacerbated existing backlogs. For instance, Airbus needs about ten years to fulfill its backlog of 7,200 A320 aircraft orders, while Boeing faces a similar ten-year timeline for its 4,800 737 aircraft orders. Increasing output is logical given the current demand, with aircraft production expected to rise significantly through 2029. McKinsey’s analysis identifies six critical focus areas for successfully scaling production: sales and operations planning, supply chain, inventory management, shop floor operations, talent, and change management. Companies excelling in these areas have increased production volumes by 10% and improved rework efficiency by 40%.

Industrial Software Market Update [Houlihan Lokey]

Are Manufacturing Jobs Really That Good? [Economist]

In the ongoing debate over manufacturing jobs, politicians like Joe Biden emphasize their importance as "good" jobs that could improve workers' lives and bolster the economy. Biden's approach includes substantial subsidies for new factories, while Donald Trump advocates for tariffs to promote American manufacturing. This focus stems from a belief that reversing the decline in manufacturing jobs would benefit workers. However, the Economist’s Bartleby remains skeptical. Despite historical notions that manufacturing jobs are superior—dating back to Adam Smith and the Industrial Revolution—the reality has often been less glamorous. Early factories were dangerous and monotonous, epitomized by Henry Ford's assembly lines, where workers found little fulfillment. Even in the post-war years, the phrase "blue-collar blues" reflected dissatisfaction among factory workers. Proponents of modern manufacturing argue that conditions have vastly improved with safer environments, automation, and white-collar roles. Yet, empirical data from sources like America's Bureau of Labour Statistics and British studies suggest that job quality in manufacturing is not necessarily superior to services across metrics like pay, benefits, job security, and safety. Moreover, the once-observed wage premium for manufacturing jobs has eroded in recent years, challenging the notion of their economic superiority. Concerns about manufacturing jobs' cyclicality and susceptibility to automation further complicate the narrative that they provide greater job security or satisfaction than service-sector roles. Instead of romanticizing a potentially flawed past, policymakers should focus on equitable regulations and ensuring decent work standards across industries. Companies will also play a crucial role, as evidence shows that well-treated employees yield better outcomes.

🎤 Upcoming Events

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!