🚀 Shaping the Future - Issue 64

Come share your experiences, stories, questions, and what you have learned in a safe, non-commercial environment as we seek to understand the state of the market.

🚨Unleash Your Potential in the Digital Renaissance

Join industry veteran Jason Bean for a groundbreaking workshop that bridges millennia of human knowledge with cutting-edge AI technology. This workshop is perfect for professionals looking to leverage AI in their work, leaders aiming to guide their teams through the AI revolution, and curious individuals wanting to understand and shape the future of AI.

Date: November 12th, 3 PM

In this intensive, interactive session, you will:

Engage in hands-on exercises to sharpen your critical AI engagement skills

Learn strategies to balance AI insights with human expertise

Gain practical techniques for continuous learning in the rapidly evolving AI landscape

Master the MASTER framework for effective prompt engineering:

- Map the Role

- Accumulate Examples

- Search Using Web Tools

- Translate Insights

- Elaborate Narratives

- Refine Questions

About This WorkshopUnlike typical tech workshops, this unique session blends philosophical insights with practical AI skills. You’ll learn how to:

Apply Socratic questioning to enhance your AI interactions and avoid common pitfalls

Develop a polymathic approach to problem-solving using GenAI

Navigate the ethical challenges of AI with newly developed "digital virtues", digital humility, algorithmic empathy and data stewardship

Explore the concept of the "Digital Renaissance" and your role in shaping it

📣 MESA Smart Manufacturing Community: Smart Connected Factory

Come share your experiences, stories, questions, and what you have learned in a safe, non-commercial environment. We seek to understand the state of the market, understand what companies have done that has or has not worked, documenting questions that MESA and the community can help answer. Overall, the goal is to accelerate each participant’s learning and progress toward Smart Manufacturing.

Topic: Real-time Applications of AI in Smart Manufacturing

Date & Time: Wednesday, November 13, 2024 (11:00 AM - 12:00 PM) (EST)

Agenda:

Thanks to our Sponsor(s)

Facilitator introduction

Community & Group overview – why participate and what to expect

Smart Manufacturing Paradigm

Thanks to our Sponsor(s)

Summary of last meeting

Today's subject

Wrap up

Next meeting

How to keep the conversation going

Thanks

🧠IIoT World ICS Cybersecurity Day 2024

In an era where industrial systems are increasingly digitized and interwoven, IIoT World ICS Cybersecurity Day is a beacon of knowledge, offering unparalleled insights into protecting critical infrastructure from cyber threats. Participants will gain a comprehensive understanding of evolving attack vectors, emerging defense strategies, and best practices to fortify industrial control systems. With top-tier experts sharing their expertise and fostering networking opportunities, this event is an invaluable resource for professionals determined to strengthen the digital backbone of modern society.

Empowering Innovation: IIoT Insights and Opportunities for Businesses and Society

Date & Time: Thursday, October 17, 2024

📚What we’ve read this week

How Foreign Investment Is Boosting U.S. Manufacturing [HBR]

In August 2022, the United States enacted the CHIPS and Science Act and the Inflation Reduction Act, committing hundreds of billions of dollars to revitalize domestic manufacturing, particularly in sectors like semiconductors, batteries, and electric vehicles. This investment has led to a surge in U.S. manufacturing construction in 2024, more than three times the level in 2019. A significant but often overlooked driver of this growth is foreign direct investment (FDI). Over 40% of the largest manufacturing "megadeals" (factories requiring over $1 billion in investment) since 2021 are FDI projects. For instance, two of the four largest semiconductor manufacturing investments since 2020 were made by foreign companies. South Korean firms Hyundai and LG are each investing more than $5 billion to build battery supply chains in the U.S. Even American companies like Ford partner with foreign firms such as South Korea-based SK On in joint ventures worth billions. Research indicates that foreign-owned factories are often more productive, higher-paying, and technologically advanced than their domestic counterparts because they are typically industry leaders capable of investing abroad. Every job created by FDI in manufacturing is associated with an additional $13,400 in wages and $135,000 in additional revenues for regional workers and firms. These benefits, however, are not guaranteed and depend on foreign firms investing in local ecosystems and sharing knowledge. Successful examples like BMW's investment in South Carolina show how investing in regional workforce development can transform local industries, turning South Carolina into an automotive powerhouse with productivity almost double the national average. Conversely, failures like Volkswagen's 1970s investment in Pennsylvania highlight that benefits are not automatic. The new wave of manufacturing projects, including those in Columbus, Ohio, and Phoenix, Arizona, can learn from these lessons by investing in regional talent development and fostering openness to share knowledge, ensuring long-term success that benefits foreign investors and domestic industries.

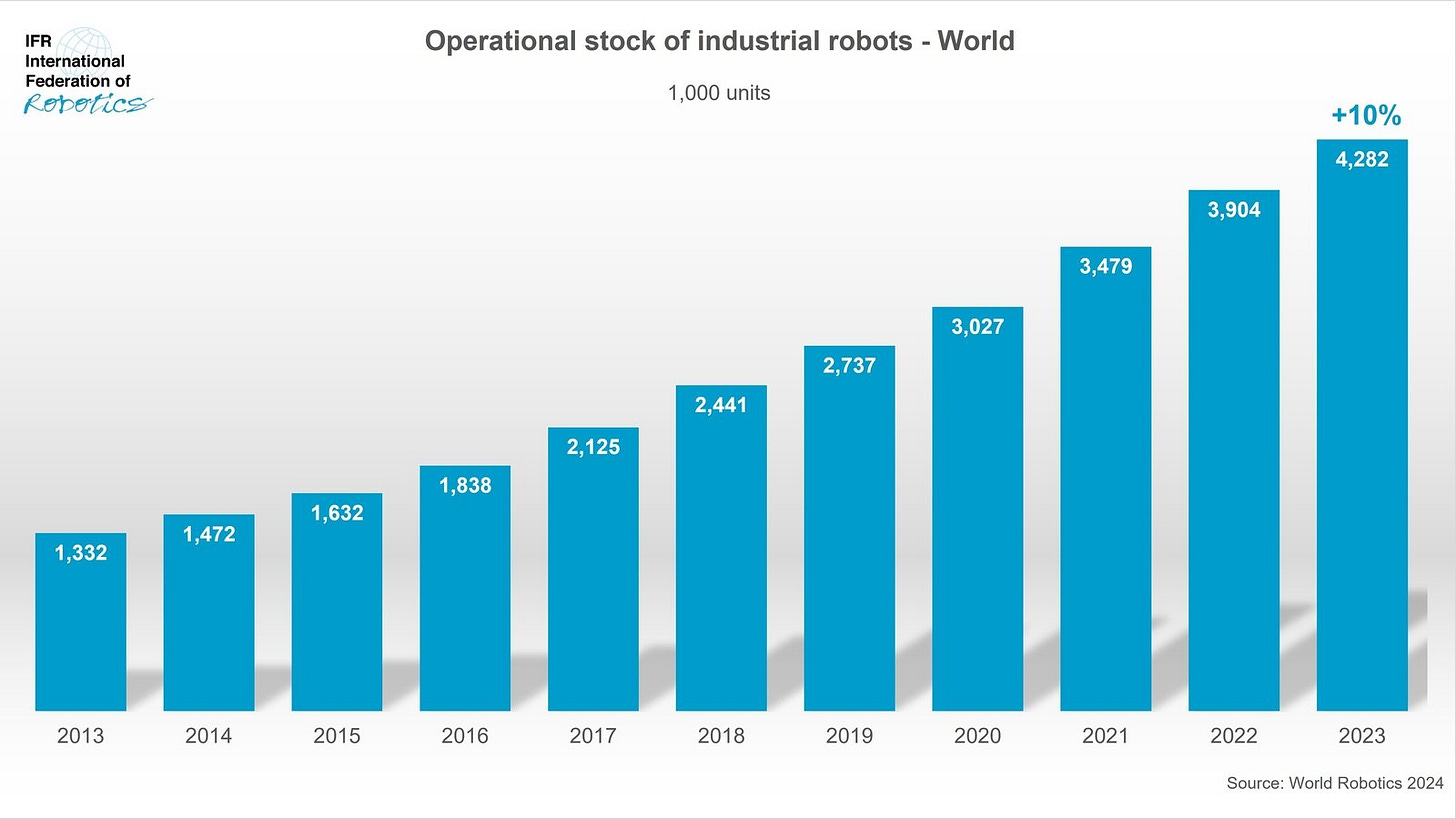

2024 International Federation of Robotics Report [IFR]

According to the 2024 World Robotics report, the number of operational industrial robots worldwide has reached a record high of 4,281,585 units, marking a 10% increase from the previous year. Annual installations exceeded half a million units for the third consecutive year, with 541,302 units installed in 2023, making it the second-highest year in history—only 2% lower than the peak in 2022. By region, 70% of all newly deployed robots in 2023 were installed in Asia, 17% in Europe, and 10% in the Americas. China solidified its position as the world's largest market, installing 276,288 industrial robots in 2023, representing 51% of global installations. This is China's second-highest level ever recorded (2022 saw 290,144 units). The share of Chinese manufacturers in the domestic market surged to 47% in 2023 from an average of 28% over the past decade. China's operational stock neared 1.8 million units, making it the first and only country with such a vast robot population. Europe saw industrial robot installations rise by 9% to a new high of 92,393 units, driven by solid investment in the automotive industry across countries like Spain (+31%), Slovakia (+48%), and Hungary (+31%). In the Americas, installations remained robust, with 55,389 units in 2023, just 1% below the record set in 2022, with the United States accounting for 68% of the regional total despite a 5% decrease to 37,587 units.

MLOps: A Multiple Case Study in Industry 4.0 [Leonhard Faubel, Klaus Schmid]

Abstract: As Machine Learning (ML) becomes more prevalent in Industry 4.0, a growing need exists to understand how systematic approaches to bringing ML into production can be practically implemented in industrial environments. Here, MLOps comes into play. MLOps refers to the processes, tools, and organizational structures used to develop, test, deploy, and manage ML models reliably and efficiently. However, there is currently a lack of information on the practical implementation of MLOps in industrial enterprises. To address this issue, we conducted multiple case studies on MLOps in three large companies with dedicated MLOps teams. We used established tools and well-defined model deployment processes in the Industry 4.0 environment. This study describes four companies' Industry 4.0 scenarios and provides relevant insights into their implementation and the challenges they faced in numerous projects. Further, we discuss MLOps processes, procedures, technologies, and contextual variations among companies.

Higher Labor Intensity in Automotive Plants After Transitioning To EVs [Nature]

Abstract: It has been widely suggested that the transition to battery electric vehicles will require 30% fewer assembly workers than those needed for internal combustion engine vehicles. We use publicly available vehicle production and employment datasets to show that labor intensity has increased at U.S. vehicle assembly plants that have fully transitioned to assembling battery electric vehicles. During the production ramp-up period, labor intensity increases by more than ten-fold compared to historic combustion vehicle assembly labor intensity. For one assembly site studied, labor intensity and total employment remained three times higher after a decade of electric vehicle production. Our study suggests that electric vehicle assembly sites may take over 15 years to achieve labor intensity parity with internal combustion vehicle assembly. Thus, rapid, widespread loss of employment at vehicle assembly plants is a more negligible risk than many fear. Moreover, our study calls for more regionally focused analyses of the transition’s effects on labor using data-driven and macro-level surveying approaches.

👋 Get Involved

Join the Industry 4.0 Club and be part of our vibrant community, dedicated to shaping the future of manufacturing. By actively participating, you can make a meaningful impact in advancing Industry 4.0 and contribute to reshaping the manufacturing landscape.

We’re always looking for new contributors to share their expertise, experience and spread the word. You can contact us directly at info@industry40club.com with subject like “Getting Involved” and follow us on all social media (LinkedIn & Twitter) or donate to help fund the club’s activities.

💬 About Shaping the Future

Shaping the Future is Industry 4.0 Club’s official newsletter. We’ll be experiencing different formats over the coming weeks until we find the one that resonates the most with our members. You can help us improve by sharing feedback and suggestions. The newsletter will land in your inbox every Sunday morning; please subscribe to not miss anything and forward the email to someone you think would benefit from this.

If you were forwarded this and found it interesting, please subscribe and share!